IiMfuno zeProjekthi

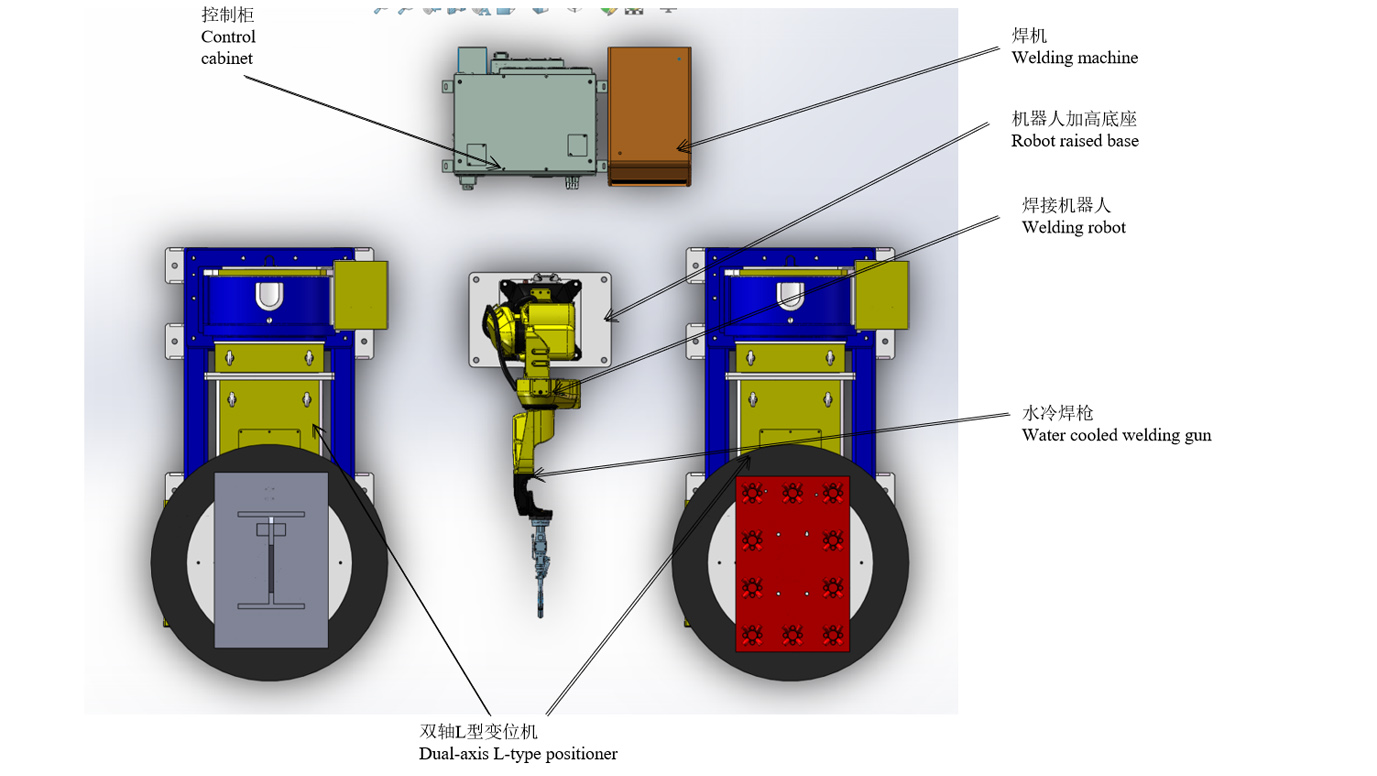

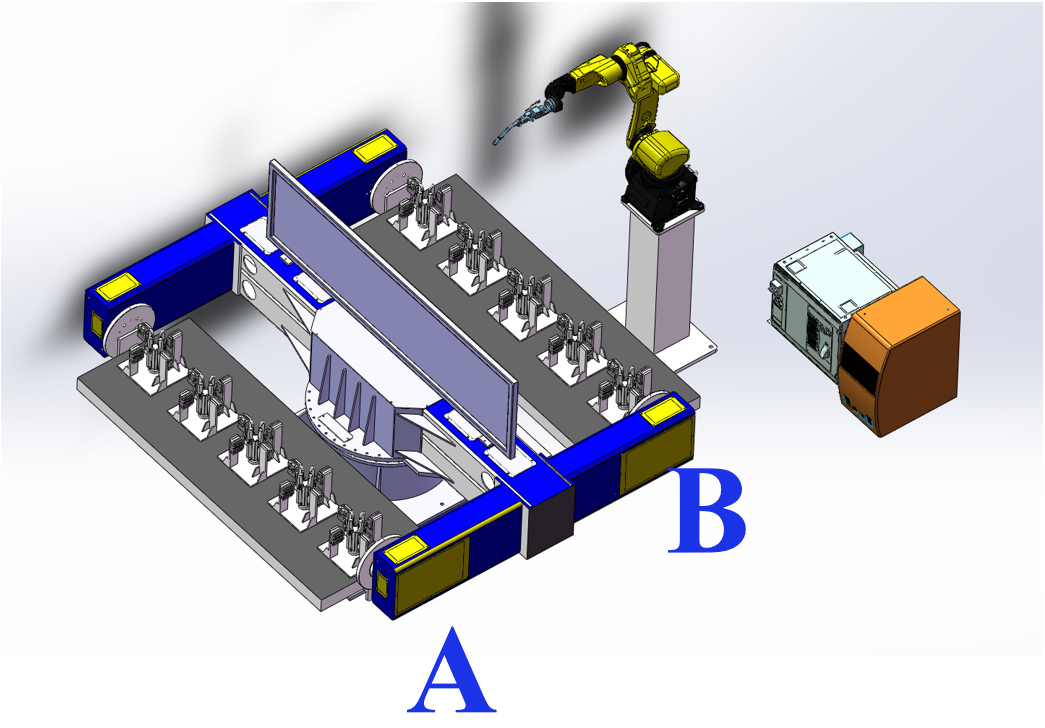

Ubeko lulonke&3D imodeli

Qaphela: Idayagram yeskim isetyenziswa kuphela kumfanekiso woyilo kwaye ayimeli ubume bomzimba besixhobo. Ubungakanani obuthile buya kumiselwa ngokwemiqathango yesiza somthengi.

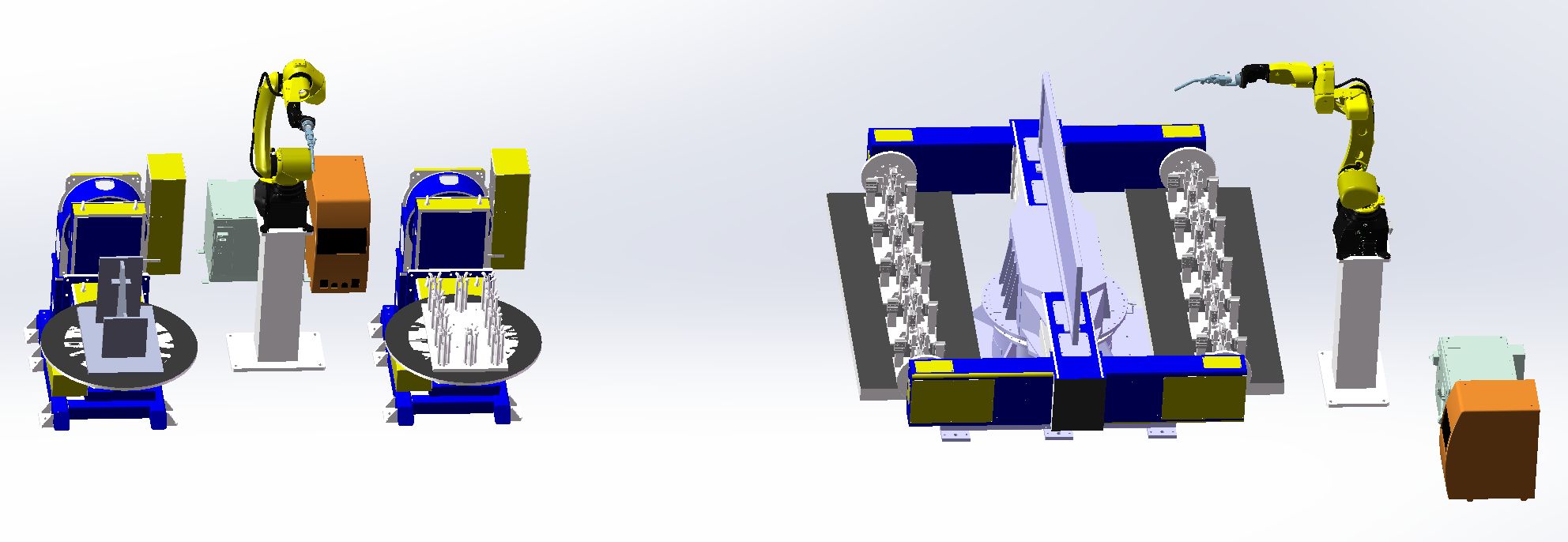

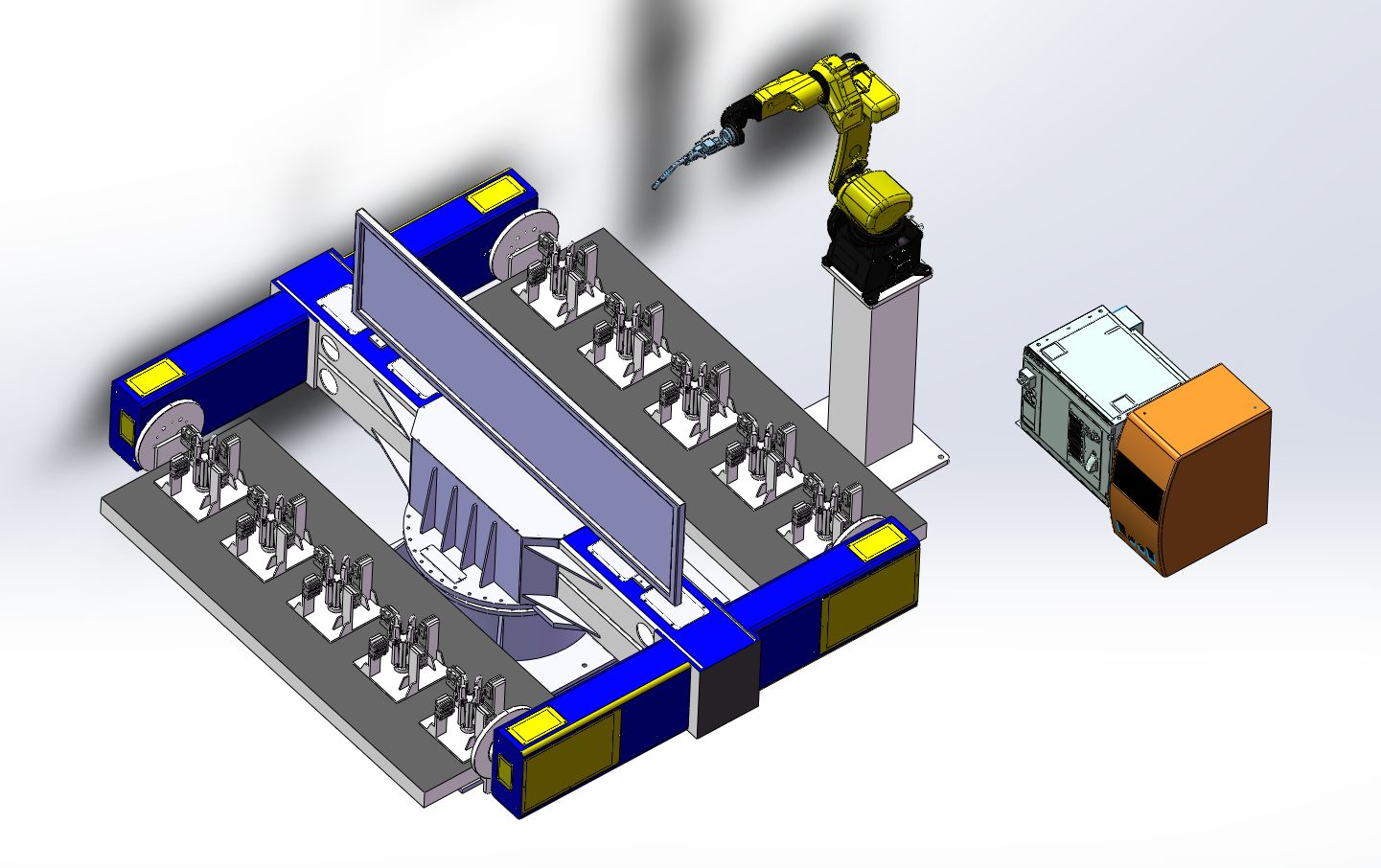

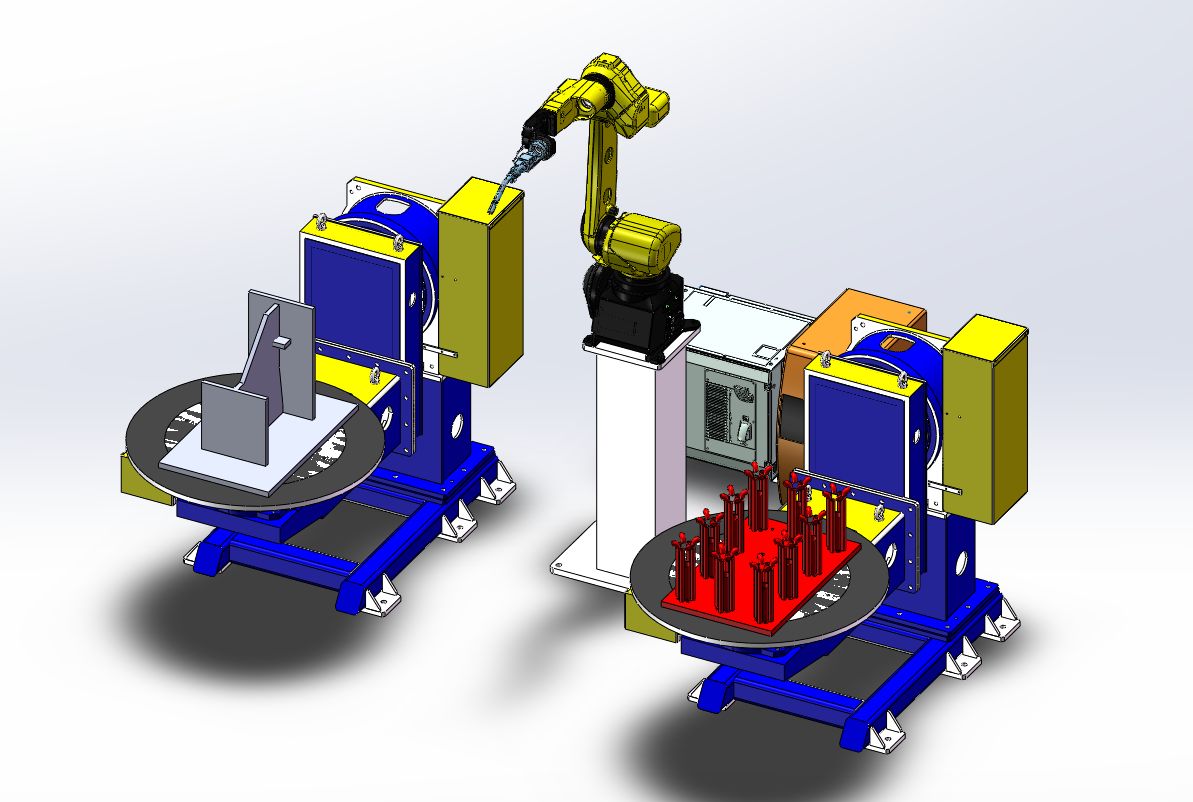

Umzobo womsebenzi womzimba kunye nemodeli ye3D

Umzobo womsebenzi womzimba kunye nemodeli ye-3D

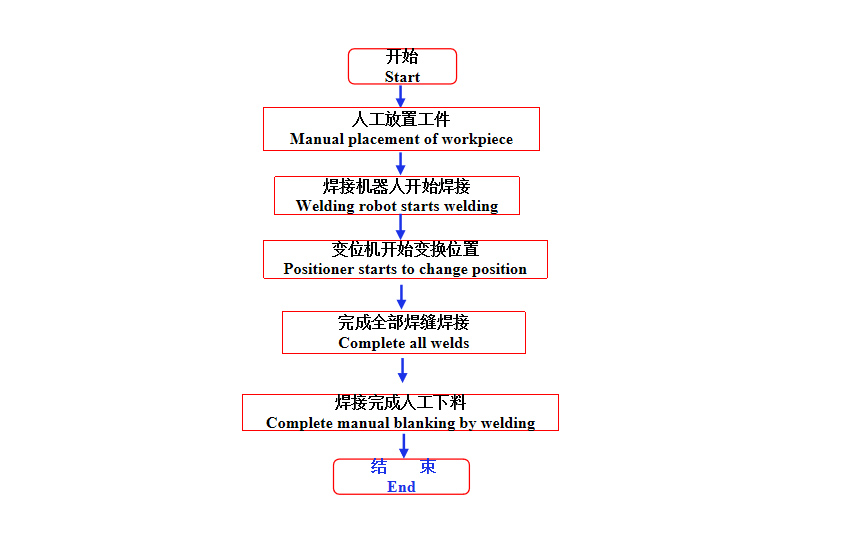

Ukuhamba komsebenzi

Imiqathango yokusebenza kwendawo yokusebenza

(1) Beka i-workpiece ngesandla kwindawo yokubeka kwaye uyilungise ngokweemfuno.

(2) Emva kokuba zonke izixhobo zivuliwe kwaye akukho alarm iboniswayo, lungiselela ukufakwa.

(3) I-robot iyayeka kwimvelaphi yomsebenzi, kwaye inkqubo yokuqhuba i-robot yinkqubo yokuvelisa ehambelanayo.

Inkqubo ye-welding ye-sleeve subassembly

1. Zifakele ngesandla iiseti ezintlanu zamalungu emikhono kwicala A.

2. Buyela kwindawo yokhuseleko ngesandla kwaye uqale iqhosha le-clamp cylinder ukuze uqinise i-workpiece.

3. Isibonisi sijikeleza de irobhothi kwicala B iqalise ukuwelda.

4. Thatha ngesandla izixhobo zokusebenza ezidityaniswe kwicala A, kunye neeseti ezintlanu zamalungu egubu.

5. Biyela ukusebenza kwezi linki zingasentla.

Ixesha le-welding yesethi nganye yemikhono yi-3min (kubandakanywa ixesha lokufakela), kunye nexesha le-welding yeesethi ze-10 yi-30min.

Inkqubo yeWelding yendibano yepleyiti efakelweyo + indibano yemikhono

1. Fakela ngesandla ipleyiti ebethelelwe kwangaphambili efakwe kwindawo yohlobo lwe-L kwicala elingu-A.

2. Qala iqhosha irobhothi welding embedded plate assembly (15min/iseti). 3.

3. Fakela ngokwenza iindawo ezikhululekileyo zendibano yemikhono kwindawo yohlobo lwe-L kwicala elingu-B.

4. Irobhothi iyaqhubeka nokuwelda indibano ye-sleeve emva kokuwelda i-embedded plate assembly(i-sleeve welding ye-10min+ufakelo lwezandla lwe-workpiece kunye ne-robot spot welding for 5min)

5. Susa indibano yepleyiti efakelweyo ngesandla.

6. I-welding manual ye-embedded plate assembly (ukususa-indawo ye-welding-loading ngaphakathi kwe-15min)

7. Fakela ngesandla ipleyiti ebethelelwe kwangaphambili kwindawo yohlobo lwe-L kwicala elingu-A.

8. Susa indibano yemikhono edityanisiweyo kwaye ufake iindawo ezisecaleni

9. Biyela ukusebenza kwezi linki zingasentla.

Ixesha lokugqitywa kwe-welding ye-welding plate yi-15min + ixesha lokugqitywa kwe-welding ye-sleeve assembly yi-15min.

Ixesha elipheleleyo 30min

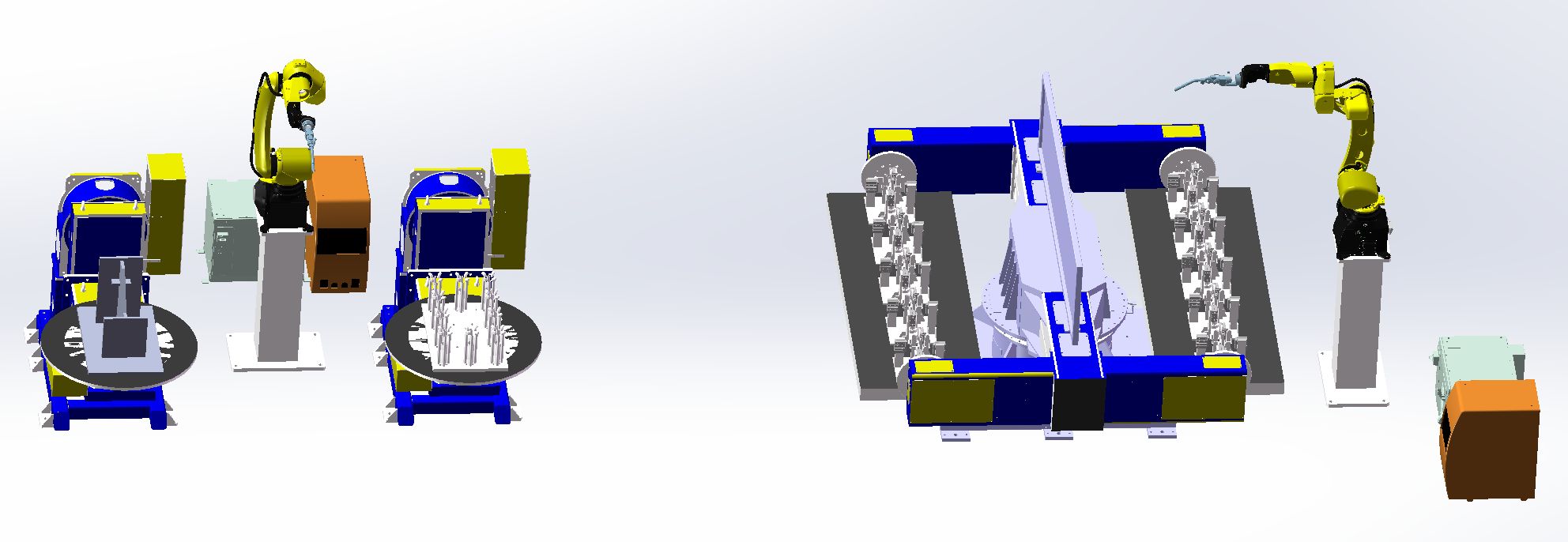

Ukwaziswa kwesixhobo soTshintsho lweTong

Ixesha le-welding ye-robot kwi-beat ekhankanywe ngasentla iyona nto yaneleyo ngaphandle kokuyeka. Ngokweeyure ezisi-8 ngosuku kunye nabaqhubi ababini, imveliso yeendibano ezimbini zizonke iiseti ezingama-32 ngosuku.

Ukwandisa imveliso:

Irobhothi enye yongezwa kwi-axis positioner ezintathu kwisikhululo se-sleesembly subassembly kwaye itshintshelwe kwi-double machine welding. Kwangaxeshanye, i-embedded plate assembly assembly+sleeve station nayo ifuna ukongeza iiseti ezimbini ze-L-type positioner kunye neseti enye yerobhothi. Ngosuku lweeyure ezisi-8 kunye nesiseko sabasebenzi abathathu, iziphumo zeendibano ezimbini zizonke zizonke iiseti ezingama-64 ngosuku.

Uluhlu lweZixhobo

| Into | S/N | Igama | Qty. | INGXELO |

| Iirobhothi | 1 | RH06A3-1490 | 2 iiseti | Ibonelelwe ngu Chen Xuan |

| 2 | Ikhabhinethi yolawulo lwerobhothi | 2 iiseti | ||

| 3 | Isiseko serobhothi esiphakanyisiweyo | 2 iiseti | ||

| 4 | Amanzi apholileyo umpu welding | 2 iiseti | ||

| Izixhobo zeperipheral | 5 | Welding Power Source MAG-500 | 2 iiseti | Ibonelelwe ngu Chen Xuan |

| 6 | I-Dual-axis ye-L-type positioner | 2 iiseti | ||

| 7 | Indawo ejikelezayo ene-axis emithathu ethe tyaba | Iseti e-1 | Ibonelelwe ngu Chen Xuan | |

| 8 | Ulungiso | Iseti e-1 | ||

| 9 | Gun Cleaner | Seta | Ukhetho | |

| 10 | Izixhobo zokususa uthuli | 2 iiseti | ||

| 11 | Ucingo lokhuseleko | 2 iiseti | ||

| Inkonzo eNxulumeneyo | 12 | Ukufakela kunye nokugunyaziswa | 1 into | |

| 13 | Ukupakishwa kunye noThutho | 1 into | ||

| 14 | Uqeqesho lobuchwephesha | 1 into |

Inkcazo yobuGcisa

Umpu wokuwelda owakhelwe ngaphakathi opholiswe ngamanzi

1) Umpu we-welding ngamnye uya kudlula umlinganiselo we-ternary ukuqinisekisa ukuchaneka komda;

I-2) Ingxenye ye-R ye-welding gun yenziwa yindlela yokukhupha i-wax emanzi, engayi kuphazamiseka ngenxa yokushisa okuphezulu okuveliswa yi-welding;

3) Nangona i-welding gun idibanisa nomsebenzi kunye nokulungiswa ngexesha lokusebenza, isibhamu se-welding asiyi kugoba kwaye akukho mfuneko yokulungiswa kwakhona;

4) Ukuphucula umphumo wegesi yokukhusela;

5) Ukuchaneka kombhobho omnye kungaphakathi kwe-0.05;

6) Umfanekiso ubhekiselele kuphela, kwaye uxhomekeke kukhetho lokugqibela.

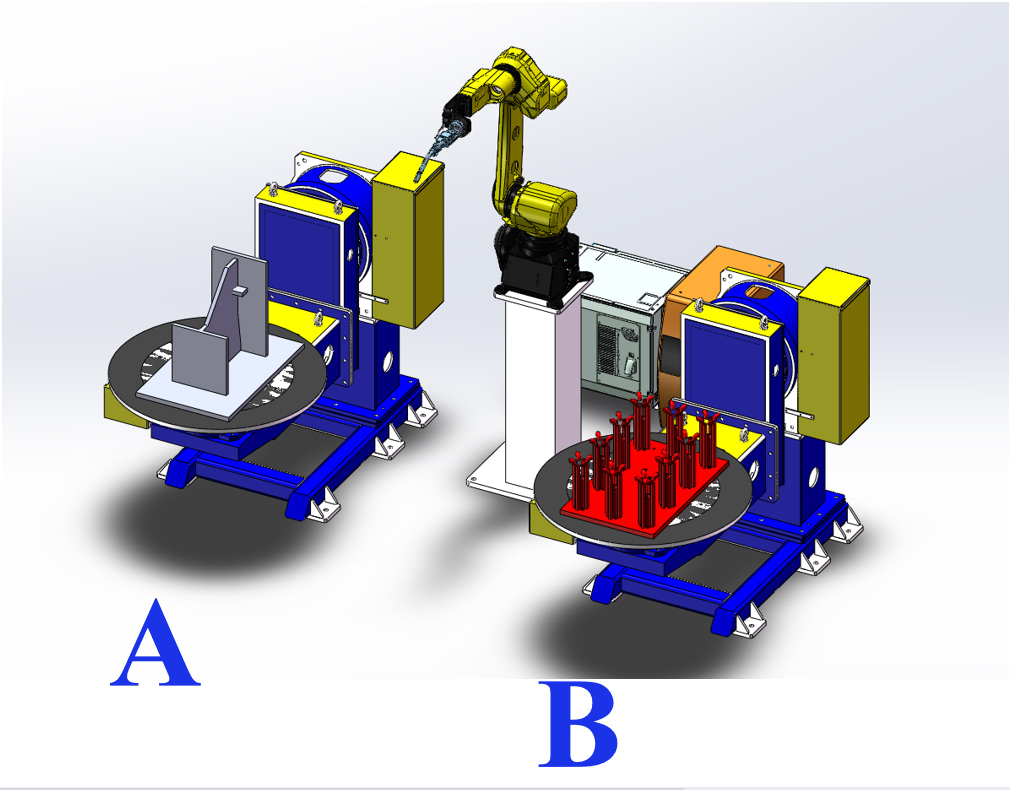

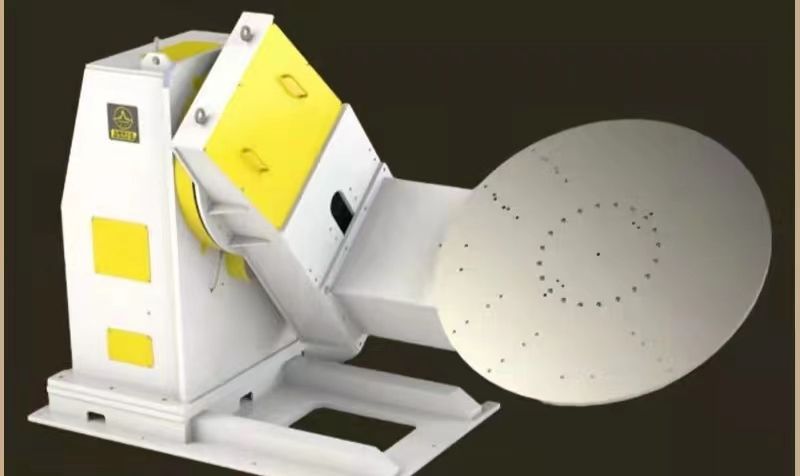

I-Dual-axis ye-L-type positioner

I-Positioner sisixhobo esikhethekileyo sokuncedisa ukuwelda, esilungele ukufuduswa kwe-welding yomsebenzi ojikelezayo, ukuze ufumane indawo efanelekileyo yomatshini kunye nesantya se-welding. Ingasetyenziswa kunye ne-manipulator kunye nomatshini we-welding ukwenza iziko le-welding elizenzekelayo, kwaye ingasetyenziselwa ukufuduswa kwe-workpiece ngexesha lokusebenza ngesandla. Imveliso eguquguqukayo ene-variable-frequency drive yamkelwa ukujikeleza kwebhentshi yokusebenza, ngokuchaneka okuphezulu kokulawulwa kwesantya. Ibhokisi yolawulo olukude inokuqonda ukusebenza okude kwebhentshi yokusebenzela, kwaye inokudityaniswa ne-manipulator kunye nenkqubo yokulawula umatshini wokuwelda ukuqonda ukusebenza okudityanisiweyo. I-welding positioner ngokuqhelekileyo yenziwe yi-rotary mechanism kunye ne-turnover mechanism ye-workbench. I-workpiece ehleliweyo kwi-workbench inokufikelela kwi-welding efunekayo kunye ne-angle yendibano ngokuphakamisa, ukuguqula kunye nokujikeleza kwe-workbench. Ibhentshi yokusebenzela ijikeleza ibe ngummiselo oguquguqukayo wesantya ongenamanyathelo, onokufumana isantya esanelisayo se-welding.

Imifanekiso yeyereferensi kuphela, kwaye ixhomekeke kuyilo lokugqibela.

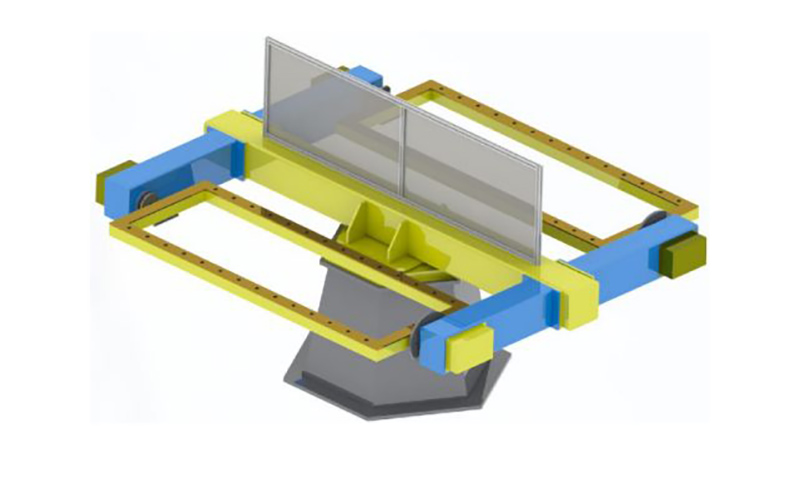

Indawo ejikelezayo ene-axis emithathu ethe tyaba

I-1) Indawo ejikelezayo ene-axis emithathu ethe tyaba iqulunqwe sisiseko esisisiseko esisisiseko, ibhokisi yokujikeleza ejikelezayo kunye nebhokisi yomsila, isakhelo se-welding, i-servo motor kunye nesinciphisi esichanekileyo, indlela yokuqhuba, isikhuselo sokukhusela kunye nenkqubo yokulawula umbane, njl.

I-2) Ngokucwangcisa ii-motor ze-servo ezahlukeneyo, i-positioner inokusebenza ngokude ngomqeqeshi we-robot okanye ibhokisi yokusebenza yangaphandle;

3) I-welding efunekayo kunye ne-angle yendibano ifezekiswa ngokuguqula i-workpiece ehleliweyo kwi-workbench;

4) Ukujikeleza kwe-workbench kulawulwa yi-servo motor, enokufikelela kwisantya esifanelekileyo se-welding;

5) Imifanekiso yenzelwe ireferensi kuphela, kwaye ixhomekeke kuyilo lokugqibela;

Ukunikezelwa kwamandla okuwelda

Ilungele ukudibanisa, ukukhwela, ukudibanisa kwekona, i-tube plate butt joint, ukudibanisa umgca we-intersection kunye nezinye iifom ezidibeneyo, kwaye inokuqonda yonke indawo ye-welding.

Ukhuseleko kunye nokuthembeka

Umatshini we-welding kunye ne-wire feeder ixhotyiswe ngokugqithisileyo, i-over-voltage kunye nokukhusela okungaphezulu kobushushu. Baye baphumelela i-EMC kunye novavanyo lokusebenza kombane olufunwa ngumgangatho wesizwe we-GB / T 15579, kwaye baphumelele isatifikethi se-3C ukuqinisekisa ukuthembeka kunye nokhuseleko ekusebenziseni.

Ukugcinwa kwamandla kunye nokukhuselwa kwendalo

Ixesha lokukhangela igesi, ixesha lokubonelela ngegesi kwangaphambili kunye nexesha lokubonelela ngegesi lag lilungelelaniswa ukuqinisekisa ukusetyenziswa okufanelekileyo kwegesi. Xa umatshini we-welding unikwe amandla, ukuba awungeni kwi-welding state ngaphakathi kwemizuzu emi-2 (ixesha elihlengahlengiswayo), liya kungena ngokuzenzekelayo kwimeko yokulala. Cima ifeni kwaye unciphise ukusetyenziswa kwamandla.

Umfanekiso ungowokukhangela kuphela, kwaye uxhomekeke kukhetho lokugqibela.

Ukunikezelwa kwamandla okuwelda

Ukucoca imipu kunye nesixhobo sokutshiza ioli ye-silicone kunye nesixhobo sokusika ucingo

I-1) Isixhobo sokutshiza ioli ye-silicone yesikhululo sokucoca isibhamu sithatha i-nozzle kabini yokutshiza, ukwenzela ukuba ioli ye-silicone ikwazi ukufikelela kwindawo yangaphakathi ye-torch torch nozzle ibhetele kwaye iqinisekise ukuba i-slag ye-welding ayiyi kubambelela kwi-nozzle.

I-2) Ukucoca isibhamu kunye nezixhobo zokutshiza ioli ye-silicone zenzelwe kwindawo efanayo, kwaye i-robot inokugqiba inkqubo yokutshiza ioli ye-silicone kunye nokucoca isibhamu ngesenzo esisodwa kuphela.

3) Ngokolawulo, umpu wokucoca kunye ne-silicone i-oil spraying device idinga kuphela isignali yokuqala, kwaye inokuqaliswa ngokulandelelana kwesenzo esicacisiweyo.

I-4) Isixhobo sokusika i-wire samkela isakhiwo sokuzimela sompu we-welding, okuphelisa isidingo sokusebenzisa i-valve ye-solenoid ukuyilawula kwaye yenza lula umbane wombane.

I-5) Isixhobo sokusika ucingo singafakwa ngokwahlukileyo okanye sifakwe kwisixhobo sokucoca i-gun kunye ne-silicone i-oyile yokutshiza i-oyile ukuze yenze isixhobo esidibeneyo, esingagcini nje ukugcina indawo yokufakela, kodwa senza ilungiselelo kunye nokulawulwa kwendlela yegesi elula kakhulu.

6) Umfanekiso ubhekiselele kuphela, kwaye uxhomekeke kukhetho lokugqibela.

Ucingo lokhuseleko

1. Misa iingcingo ezikhuselayo, iingcango zokhuseleko okanye iigrayiti zokhuseleko, izitshixo zokhuseleko kunye nezinye izixhobo, kwaye uqhube ukhuseleko oludityanisiweyo oluyimfuneko.

2. Ucango lokhuseleko luya kumiswa kwindawo efanelekileyo yocingo olukhuselayo. Zonke iingcango ziya kuxhotyiswa ngokutshintsha kunye namaqhosha okhuseleko, iqhosha lokuseta ngokutsha kunye neqhosha lokumisa likaxakeka.

3. Ucango lokhuseleko ludityaniswe nesistim ngokutshixa ukhuseleko (switch). Xa umnyango wokhuseleko uvulwe ngokungaqhelekanga, inkqubo iyayeka ukusebenza kwaye inike i-alamu.

4. Amanyathelo okhuseleko aqinisekisa ukhuseleko lwabasebenzi kunye nezixhobo ngokusebenzisa i-hardware kunye nesofthiwe.

5. Ucingo lokhuseleko lunokubonelelwa yiParty A ngokwayo. Kuyacetyiswa ukuba usebenzise i-welding yegridi ekumgangatho ophezulu kwaye ubhake ipeyinti yesilumkiso emthubi kumphezulu.

Inkqubo yoLawulo loMbane

1. Ibandakanya ulawulo lwenkqubo kunye nonxibelelwano lomqondiso phakathi kwezixhobo, kubandakanywa izinzwa, iintambo, iindawo zokubeka, iiswitshi, njl.;

2. Iyunithi ezenzekelayo yenzelwe ukukhanya kwe-alarm yemibala emithathu. Ngexesha lokusebenza okuqhelekileyo, ukukhanya kwemibala emithathu kubonisa eluhlaza; ukuba iyunithi iyasilela, ukukhanya kwemibala emithathu kuya kubonisa i-alamu ebomvu ngexesha;

3. Kukho amaqhosha okumisa kaxakeka kwikhabhinethi yokulawula irobhothi kunye nebhokisi yokufundisa. Kwimeko yonxunguphalo, iqhosha lokumisa likaxakeka linokucinezelwa ukuba liqaphele ukumisa okungxamisekileyo kwenkqubo kunye nokuthumela isignali ye-alarm ngexesha elinye;

4. Iinkqubo ezahlukeneyo zesicelo zinokuqulunqwa ngesixhobo sokufundisa, izicelo ezininzi zinokuqulunqwa, ezinokuhlangabezana neemfuno zokuphuculwa kwemveliso kunye neemveliso ezintsha;

5. Zonke iimpawu zokumisa ezingxamisekileyo zenkqubo yokulawula yonke kunye neempawu zokukhusela ukhuseleko phakathi kwezixhobo zokucubungula kunye neerobhothi zixhunyiwe kwinkqubo yokukhusela kwaye zidibene ngeprogram yokulawula;

6. Inkqubo yokulawula iqaphela uxhulumaniso lwesignali phakathi kwezixhobo zokusebenza ezifana ne-robot, i-bin yokulayisha, i-gripper kunye nezixhobo zokusebenza.

7. Inkqubo yesixhobo somatshini kufuneka iqonde utshintshiselwano lwesignali kunye nenkqubo yerobhothi.

Indawo yokusebenza (ibonelelwe liQela A)

| Ukunikezwa Amandla | Ukunikezelwa kwamandla: izigaba ezintathu ezine-wire AC380V ± 10%, i-voltage fluctuation range ± 10%, i-frequency: 50Hz; Ukunikezelwa kwamandla kwikhabhinethi yokulawula i-robot kufuneka ixhotyiswe nge-air switch ezimeleyo; Ikhabhinethi yolawulo lwerobhothi kufuneka isekelwe phantsi ngokumelana nomgangatho ongaphantsi kwe-10Ω; Umgama osebenzayo phakathi konikezelo lwamandla kunye nekhabhinethi yokulawula umbane yerobhothi ingaphakathi kweemitha ezi-5. |

| Umthombo womoya | Umoya ocinezelweyo uya kuhluzwa ukususa ukufuma kunye nokungcola, kwaye uxinzelelo lwemveliso emva kokudlula kwi-triplet iya kuba yi-0.5 ~ 0.8Mpa; Umgama osebenzayo phakathi komthombo womoya kunye nomzimba werobhothi ungaphakathi kweemitha ezi-5. |

| Isiseko | Umgangatho wesamente oqhelekileyo weworkshop yeParty A uya kusetyenziselwa unyango, kwaye iziseko zofakelo zesixhobo ngasinye ziya kumiswa emhlabeni kunye neebholiti zokwandisa; Amandla ekhonkrithi: 210 kg / cm 2; Ubukhulu bekhonkrithi: ngaphezu kwe-150 mm; Ukungalingani kwesiseko: ngaphantsi kwe ±3mm. |

| Iimeko zokusingqongileyo | Ubushushu be-Ambient: 0 ~ 45 ° C; Ukufuma okuhambelanayo: 20% ~ 75%RH (akukho condensation); Ukukhawuleza kweVibration: ngaphantsi kwe-0.5G |

| Okunye | Kuphephe ukutsha kunye neegesi ezivuthayo kunye nolwelo, kwaye musa ukutshiza ioli, amanzi, uthuli, njl.; Zigcine kude nemithombo yengxolo yombane. |