Uhlalutyo lweNkqubo yoMda weMveliso

Die retrorei im technischen prozess

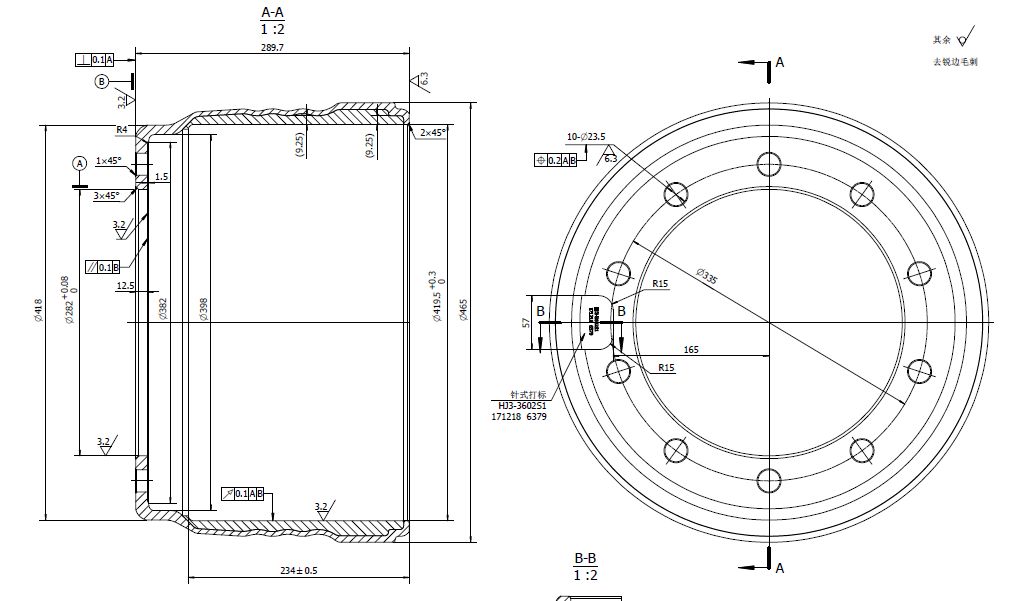

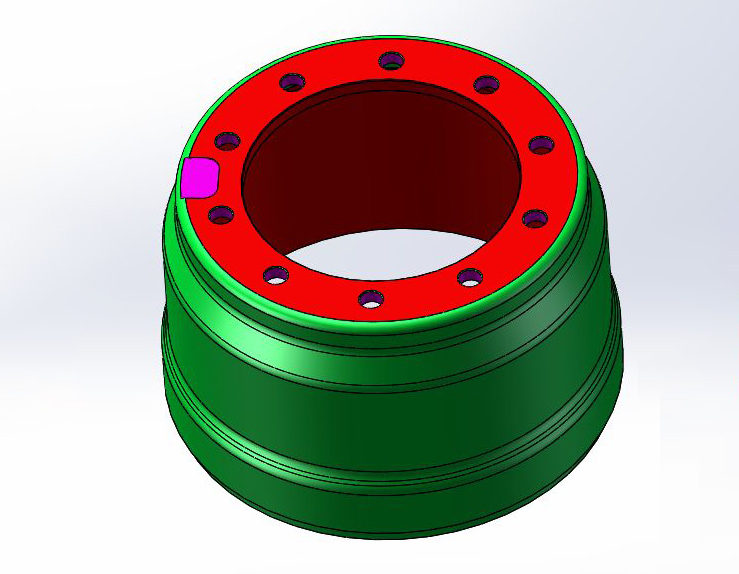

1. Inkqubo ye-clamping elahlayo yamkelwa ngexesha lokujika. Ukuguqula zonke iinxalenye ze-machining, kubandakanywa nomhlaba ophantsi wezinto zokusebenza.

2. Ngethuba lokugaya, ii-clamps ze-hydraulic ziya kusetyenziselwa ukufumana kunye nobubanzi obungaphakathi be-Φ282 kunye nobuso obuphezulu besiphelo, i-drill 10-Φ23.5 umngxuma wokunyuka kunye ne-chamfering kumacala omabini, kunye ne-mill indawo yokumakisha i-pneumatic;

Uluhlu lweZixhobo

| OP10 machining Cycle timer | |||||||||||||||

| Inkcazo yeNdlela |

| ||||||||||||||

| Umthengi | Izinto eziphathekayo | 45 | Imodeli yesixhobo somatshini | Uvimba onguNomb. | |||||||||||

| Igama lemveliso | Ukusika isixhobo shaft iinxalenye welding | Umzobo inombolo. | Umhla wokulungiselela | 2021.1.19 | Ilingiselelwe ngu | ||||||||||

| Inyathelo lenkqubo | Imela Nomb. | umxholo womatshini | Igama lesixhobo | Ukusika Ububanzi | Ukusika isantya | Isantya sokujikeleza | Ukutya ngokwenguquko nganye | ukondla ngesixhobo somatshini | Inani lokusikwa | Inkqubo nganye | ixesha Machining | Ixesha lokungenzi nto | Qinisa kwaye ukhulule | Ixesha lokutshintsha isixhobo | |

| Hayi. | Hayi. | Ukuchithwa | Izixhobo | D mm | VcM/min | R pm | mm/Rev | mm/Mzu | Amaxesha | Ubude mm | Isiqendu | Isiqendu | Isiqendu | ||

| 1 | T01 | Gcoba ubuso obungaphezulu | 455.00 | 450 | 315 | 0.35 | 110 | 1 | 20.0 | 10.89 | 3 | 3 | |||

| 2 | T02 | Lathe roughly DIA 419.5 internal bore, DIA 382 step face and DIA 282 internal bore | 419.00 | 450 | 342 | 0.35 | 120 | 1 | 300.0 | 150.36 | 3 | 3 | |||

| 3 | T03 | Lathe isiphelo sobuso ngokuchanekileyo | 455.00 | 450 | 315 | 0.25 | 79 | 1 | 20.0 | 15.24 | 3 | ||||

| 4 | T04 | I-Lathe ngokuchanekileyo i-DIA 419.5 yangaphakathi, i-DIA 382 yobuso besinyathelo kunye ne-DIA 282 yangaphakathi. | 369.00 | 450 | 388 | 0.25 | 97 | 1 | 300. 0 | 185.39 | |||||

| 5 | T05 | Lathe umva kwaye ngokurhabaxa isiphelo esisezantsi ubuso | 390.00 | 420 | 343 | 0.35 | 120 | 1 | 65.0 | 32.49 | 3 | ||||

| 6 | T06 | Lathe umva kwaye ngokuchanekileyo ubuso besiphelo esisezantsi | 390.00 | 450 | 367 | 0.25 | 92 | 1 | 65.0 | 42.45 | 3 | ||||

| Inkcazo: | Ixesha lokusika: | 437 | Isibini | Ixesha lokubamba nge-fixture kunye nokulayisha kunye nezinto ezingenanto: | 15.00 | Isibini | |||||||||

| Ixesha elincedisayo: | 21 | Isibini | Iiyure zomsebenzi zizonke: | 472.81 | Isibini | ||||||||||

| OP20 machining Cycle timer | |||||||||||||||

| Inkcazo yeNdlela |  | ||||||||||||||

| Umthengi | Izinto eziphathekayo | HT250 | Imodeli yesixhobo somatshini | Uvimba onguNomb. | |||||||||||

| Igama lemveliso | Qhuba igubu | Umzobo inombolo. | Umhla wokulungiselela | 2021.1.19 | Ilingiselelwe ngu | ||||||||||

| Inyathelo lenkqubo | Imela Nomb. | umxholo womatshini | Igama lesixhobo | Ukusika Ububanzi | Ukusika isantya | Isantya sokujikeleza | Ukutya ngokwenguquko nganye | ukondla ngesixhobo somatshini | Inani lokusikwa | Inkqubo nganye | ixesha Machining | Ixesha lokungenzi nto | Qinisa kwaye ukhulule | Ixesha lokutshintsha isixhobo | |

| Hayi. | Hayi. | Ukuchithwa | Izixhobo | D mm | VcM/min | R pm | mm/Rev | mm/Mzu | Amaxesha | Ubude mm | Isiqendu | Isiqendu | Isiqendu | ||

| 1 | T01 | Gqoka 10-DIA 23.5 umngxuma onyukayo | I-drill ephantsi komngxuma DIA 23.5 | 23.50 | 150 | 2033 | 0.15 | 305 | 10 | 15.0 | 29.52 | 20 | 5 | ||

| 2 | T04 | 10-DIA 23 Orifice Chamfering | DIA 30 compound reaming chamfering cutter | 30.00 | 150 | 1592 | 0.20 | 318 | 10 | 3.0 | 6.65 | 20 | 5 | ||

| 3 | T06 | 10-DIA 23.5 Ngasemva orifice chamfering | DIA 22 reverse chamfering cutter | 22.00 | 150 | 2171 | 0.20 | 434 | 10 | 3.0 | 4.14 | 40 | 5 | ||

| 4 | T08 | Indawo yokuMakisha yokuSila | DIA 30 square igxalaba lokusila | 30.00 | 80 | 849 | 0.15 | 127 | 1 | 90.0 | 42.39 | 4 | 5 | ||

| Inkcazo: | Ixesha lokusika: | 82 | Isibini | Ixesha lokubamba nge-fixture kunye nokulayisha kunye nezinto ezingenanto: | 30 | Isibini | |||||||||

| Ixesha elincedisayo: | 104 | Isibini | Iiyure zomsebenzi zizonke: | 233.00 | Isibini | ||||||||||

Intshayelelo kumgca weMveliso

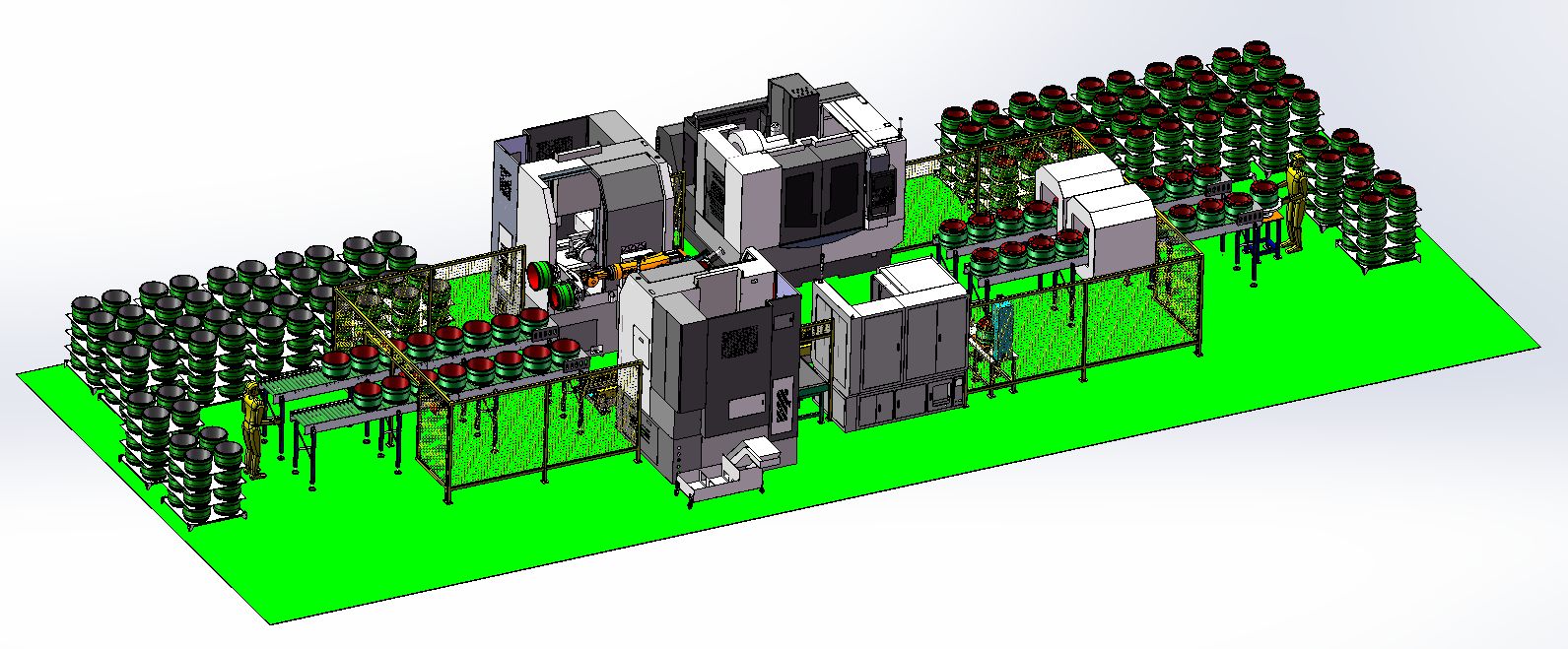

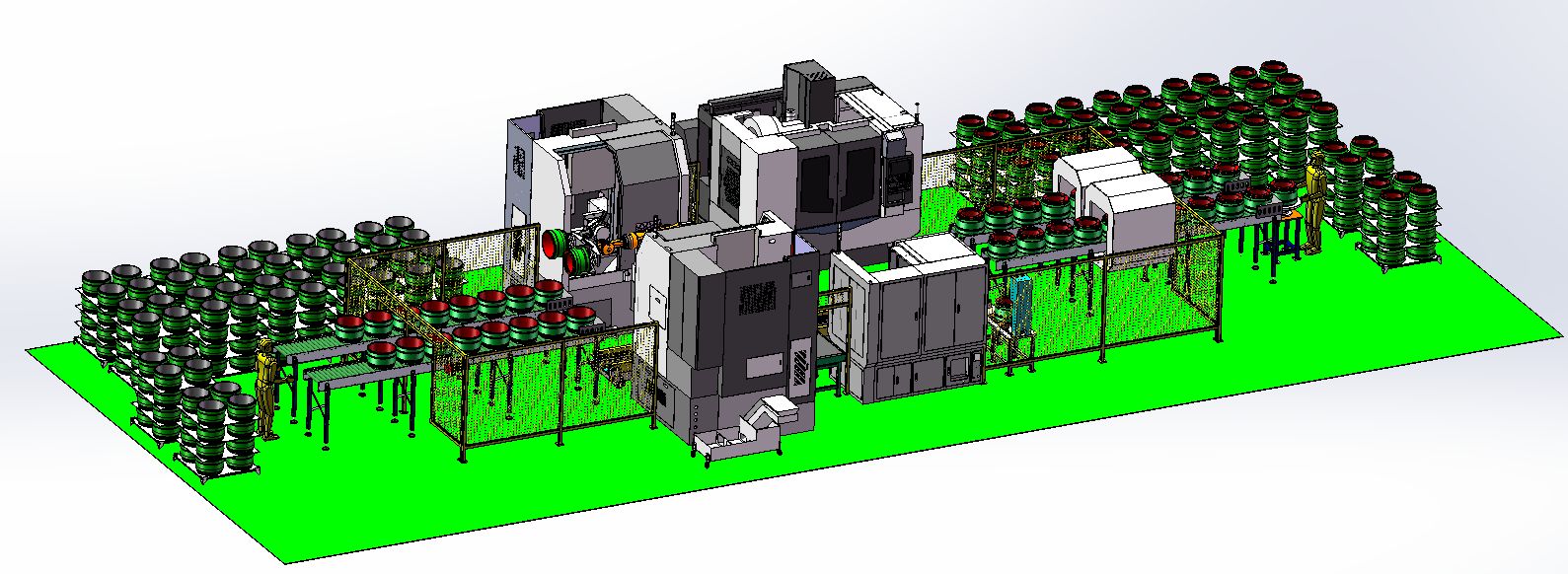

Uyilo lomgca weMveliso

Intshayelelo kumgca weMveliso

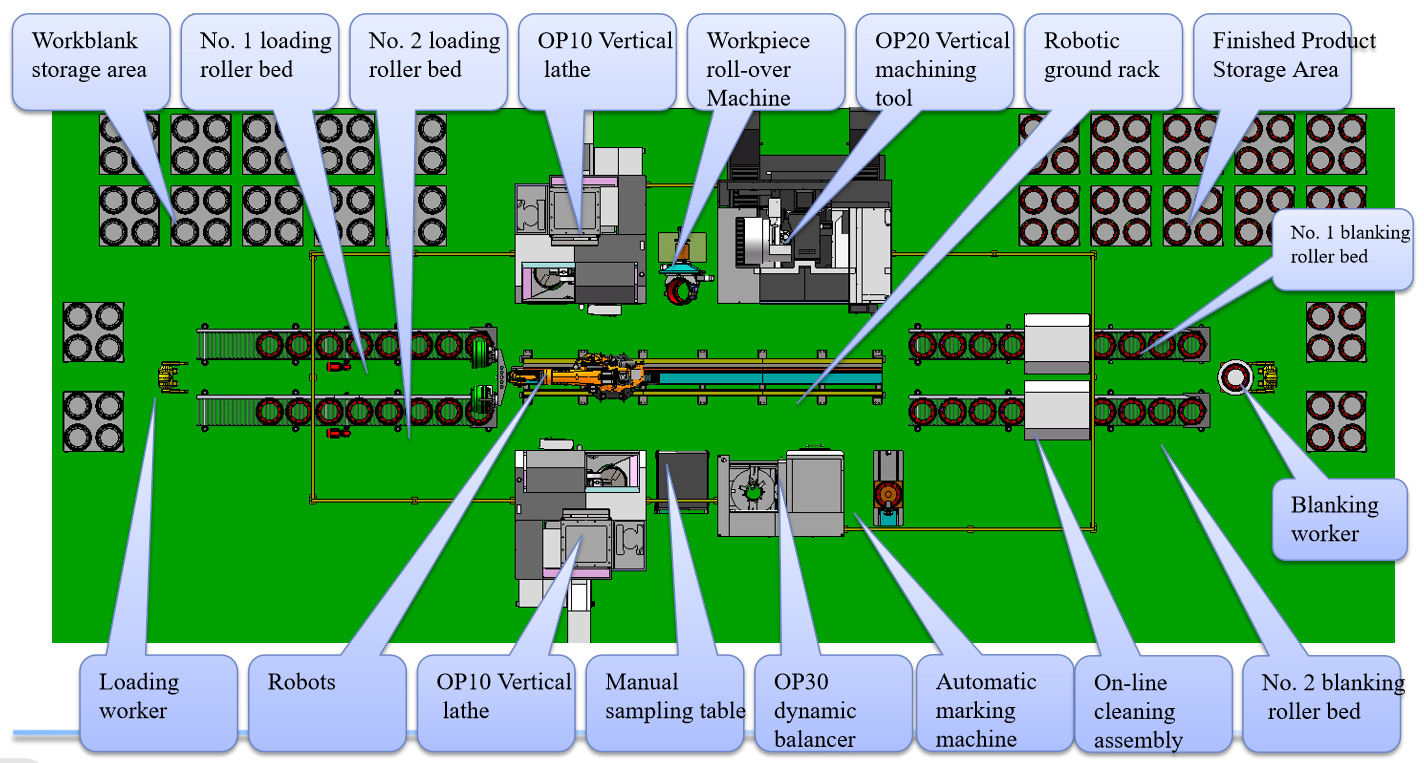

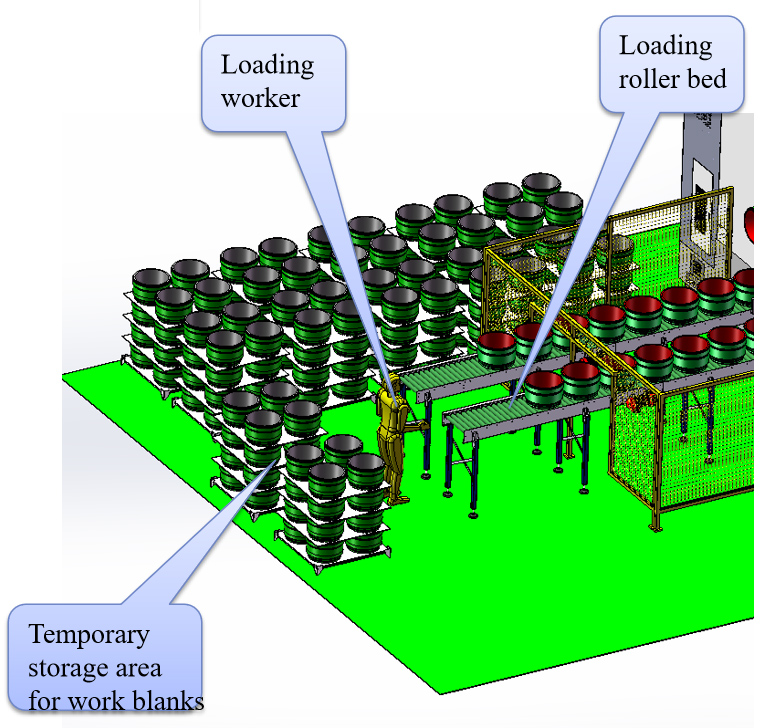

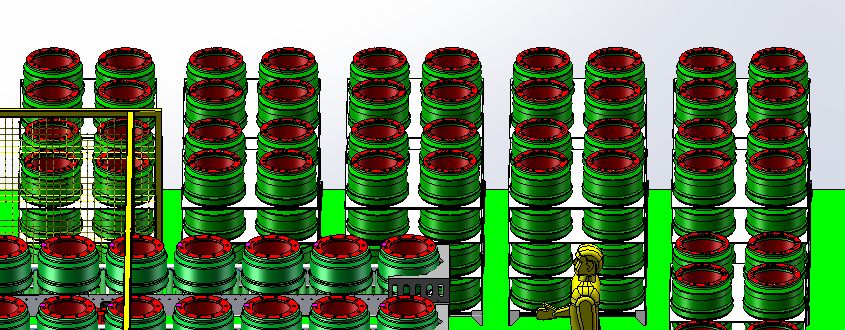

Umgca wemveliso uquka iyunithi yokulayishwa kwe-1, iyunithi ye-lathe yomatshini kunye neyunithi e-1 engenanto. Iirobhothi zothutho izixhobo phakathi kwezikhululo ngaphakathi kweyunithi nganye. Ii-forklift zibeka iibhaskithi phambi kokulayisha kunye neeyunithi ezingenanto; Umgca wemveliso uquka indawo: 22.5m×9m

Inkcazo yomgca wemveliso

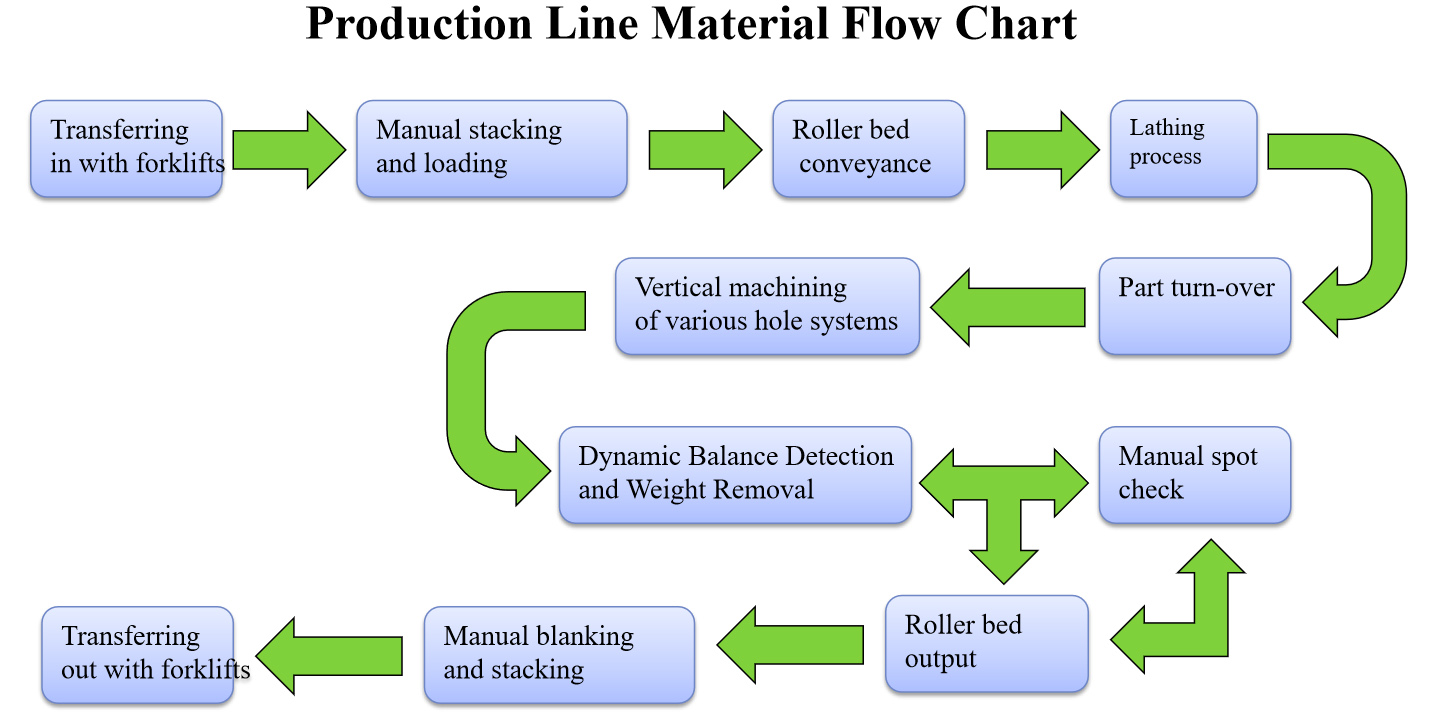

1. Izithuba zomsebenzi zithuthwa kwizikhululo zokulayisha nge-forklifts, ziphakanyiswe ngesandla kwi-roller bed, kwaye zithunyelwe kwizikhululo zokulayisha ngee-roller. Ukulayishwa kunye nokulayishwa komatshini wokulinganisa kwinkqubo ye-lathe, inkqubo yokuqengqeleka kunye ne-drilling kunye nenkqubo yokugaya igqitywe ngamarobhothi. Iimveliso ezigqityiweyo zithunyelwa kwizikhululo ezingenanto ngokusebenzisa ibhedi ye-roller, kwaye ithunyelwe nge-forklifts emva kokunyusa ngesandla kunye nokupakisha;

2. Izikrini ezinkulu zokubonisa i-elektroniki ziya kusekwa kwiintambo zothumelo lothutho ukuze zihlaziye kwaye zibonise ulwazi lwemveliso, iimveliso ezineziphene kunye neentsuku zokuvelisa ukhuseleko ngexesha langempela;

3. Umgca wothumelo uya kubonelelwa ngokukhanya okulumkisayo kwiyunithi nganye, enokubonisa ulwazi olufana nolwesiqhelo, ukungabikho kwemathiriyeli kunye nokothusa;

4. Umgca ozenzekelayo uthatha imowudi yokucubungula iyunithi kunye nemowudi ye-wiring yeyunithi, kunye nesakhiwo esiguquguqukayo, esifanelekileyo kwiimfuno ezahlukeneyo zokubeka abathengi;

5. Yamkela i-robot edibeneyo yokulayisha kunye ne-blanking, enozinzo oluphezulu, ukugcinwa okufanelekileyo kunye nobomi benkonzo ende;

6. Imfuno encinci yabasebenzi. Iimfuno zabasebenzi bemihla ngemihla kwishifti nganye yalo mgca uzenzekelayo zimi ngolu hlobo lulandelayo:

I-Forkliftman 1 ~ 2 abantu (abaphethe ukuphakamisa, ukunyusa i-forklifting kunye nokudlulisa izithuba zomsebenzi / iimveliso ezigqityiweyo)

Injineli yoLondolozo ngumntu omnye (ophethe ulondolozo lwesiqhelo-i-oyile kunye nabasiki bamanzi, njl.njl.)

7. Umgca ozenzekelayo unokwandiswa okunamandla. Njengomatshini wocingo oluxubeneyo, ukulandeleka komsebenzi kunye neminye imisebenzi, kunye neendleko eziphantsi zokwandisa;

Ilayisha iyunithi

1. Umgca we-roller bed yokulayisha unokugcina i-12 × 16 = iziqwenga ze-192; 2. Vula i-stack ngesandla kwaye uyiphakamise kwibhedi ye-roller yokulayisha kwaye uyithumele kwisikhululo sokulayisha ngumqhubi we-roller; 3. Emva kokuvula i-stack, i-tray engenanto iya kunyanzeliswa kwaye ibekwe kumgca ongenanto weetreyi ezingenanto, ukupakishwa kwii-8 layers, kunye ne-tray stacking engenanto iya kususwa ngesandla kwaye ibekwe kwindawo yokugcina;1. Umgca we-roller bed yokulayisha unokugcina i-12 × 16 = iziqwenga ze-192;

2. Vula i-stack ngesandla kwaye uyiphakamise kwibhedi ye-roller yokulayisha kwaye uyithumele kwisikhululo sokulayisha ngumqhubi we-roller;

3. Emva kokuvula i-stack, i-tray engenanto iya kunyanzeliswa kwaye ifakwe kumgca ongenanto weetreyi ezingenanto, ukupakisha kwii-8 layers, kunye ne-tray stacking engenanto iya kususwa ngesandla kwaye ibekwe kwindawo yokugcina;

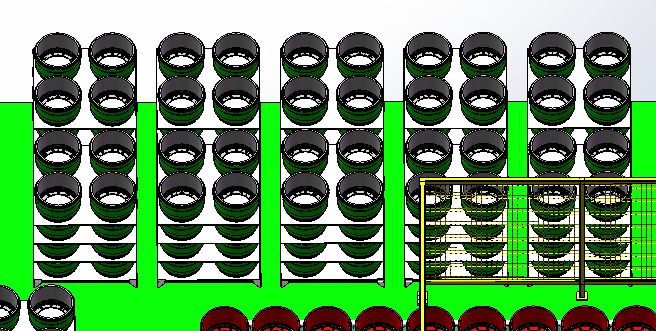

Intshayelelo yokusebenza izitaki ezingenanto

1. Isitaki esinye seziqwenga eziyi-16 kunye nemigangatho emi-4 iyonke, kunye neeplati zokuhlukanisa phakathi koluhlu ngalunye;

2. Isitaki esingenanto somsebenzi singagcina iziqwenga ezingama-160;

3. I-pallet icetyiswa ukuba ilungiswe ngumthengi. Imfuneko: (1) Ukuqina okuhle kunye nokuthe tyaba (2) ukukwazi ukubanjwa yirobhothi.

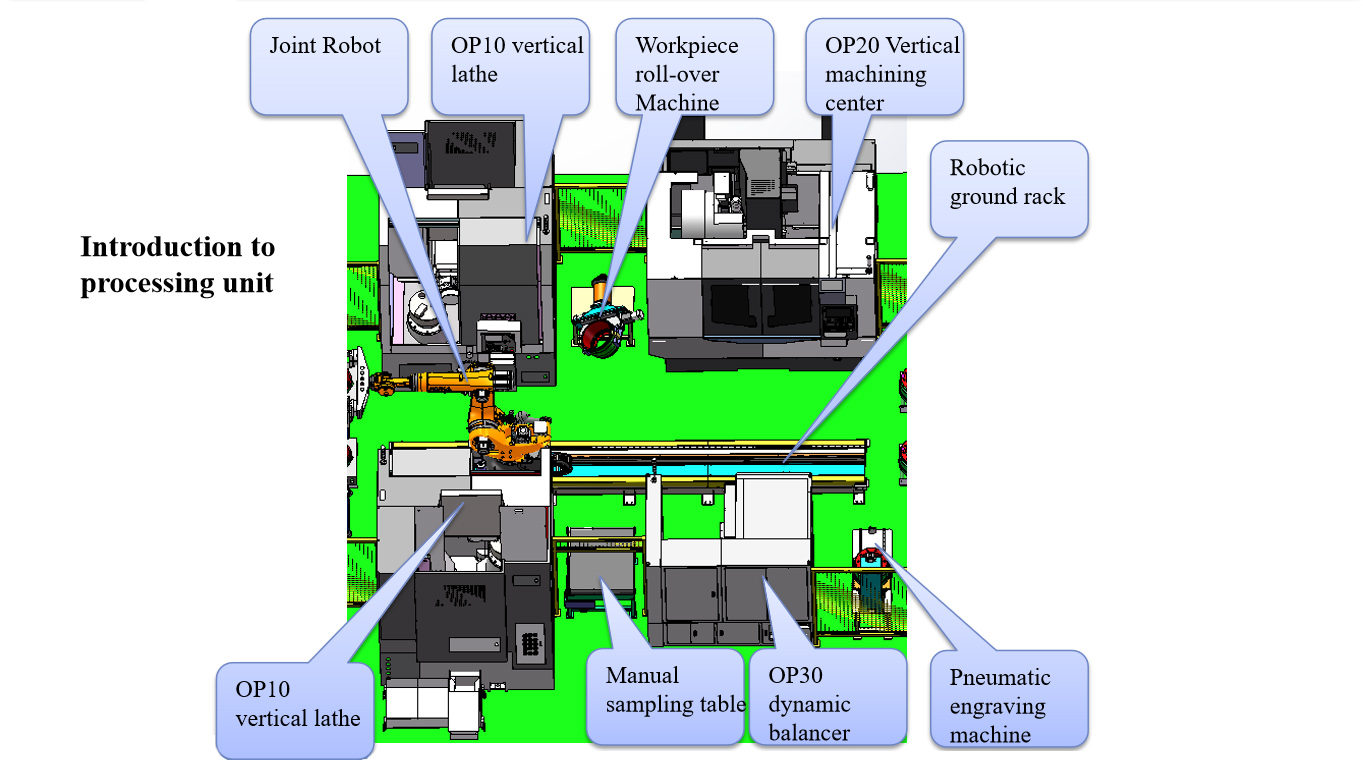

Intshayelelo kwiyunithi yokusebenza

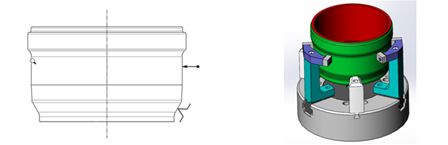

1. Inkqubo ye-lathing iqukethe iileyile ezimbini ezithe nkqo, i-robot ye-1 kunye ne-robot ground rack, eyenza ukucwangciswa kwesangqa sangaphandle, umphezulu wesinyathelo somngxuma wangaphakathi kunye nobuso besiphelo senxalenye;

2. Isikhululo sokuqengqeleka sinomatshini om-1 oqengqelekayo, owenza iinxalenye eziziqengqelekayo;

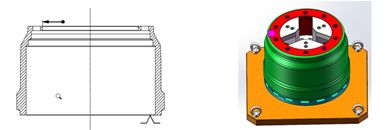

3. Inkqubo yokugaya kunye nokugaya iquka i-1 machining center kunye ne-robot enye ye-2, eyenza ukulungiswa komgodi wofakelo kunye nommandla wokumakisha le nxalenye.

4. Inkqubo yokulinganisa kunye nokususa ubunzima iquka isilinganisi esithe nkqo esiguquguqukayo, esenza ubhaqo lwe-dynamic balancing kunye nokususa ubunzima bamalungu;

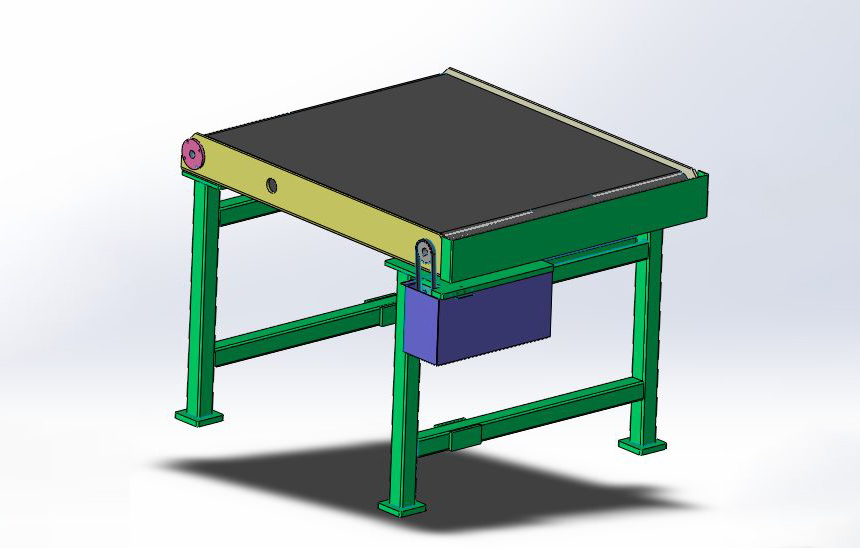

5. Isikhululo sokutshekisha senziwe ngesandla sinesixhobo sokuhambisa ibhanti, esenza uthutho lweendawo ezijongiweyo kwaye sisetyenziswe njengeqonga lokuhlola;

6. Isikhululo sokusebenza somatshini wokubhala we-pneumatic wenza umsebenzi wokukrola kunye nokumakisha zonke iimveliso;

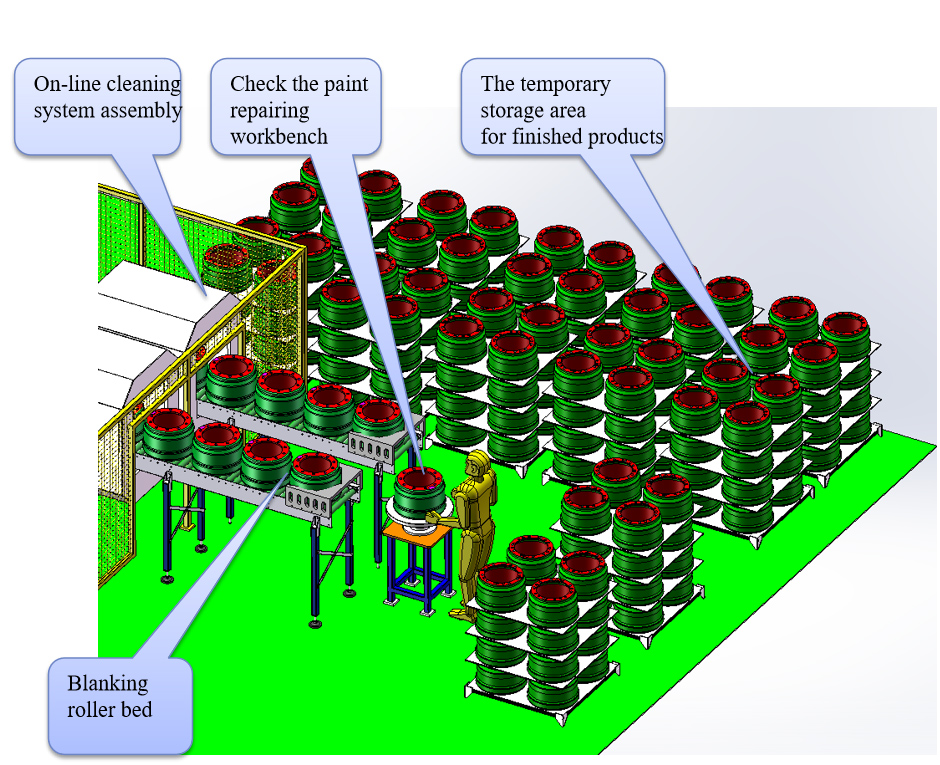

Intshayelelo yeyunithi engenanto

1. Umgca we-roller bed yokulayisha unokugcina i-12 × 16 = iziqwenga ze-192;

2. Iitreyi kunye neepleyiti zokwahlula kwisikhululo sokulayisha zihanjiswa kwindawo engenanto ngeeforklifts;

3. Iimveliso ezigqityiweyo zithuthelwa kwisikhululo esingenanto nge-roller conveyor, kwaye iphakanyiswe kwaye ifakwe ngesandla kwaye idluliselwe nge-forklifts;

Ukuqaliswa kokupakishwa kwemveliso egqityiweyo

1. Isitaki esinye seziqwenga eziyi-16 kunye nemigangatho emi-4 iyonke, kunye neeplati zokuhlukanisa phakathi koluhlu ngalunye;

Iziqwenga ze-2.192 zinokugcinwa kwi-stack yeemveliso ezigqityiweyo;

3. I-pallet icetyiswa ukuba ilungiswe ngumthengi. Imfuneko: (1) Ukuqina okuhle kunye nokuthe tyaba (2) ukukwazi ukubanjwa yirobhothi.

Ukuqaliswa kwamacandelo aphambili asebenzayo omgca wemveliso

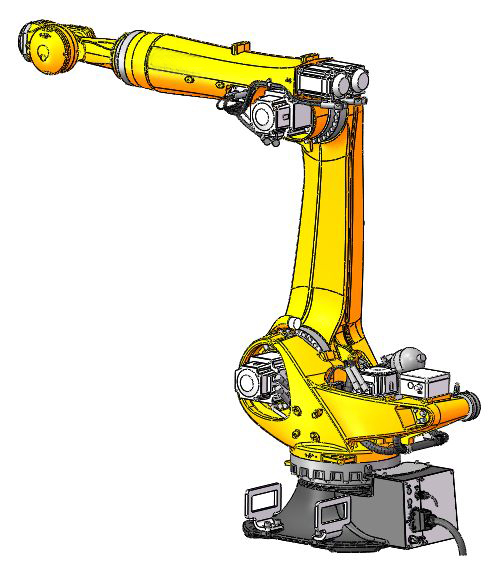

Intshayelelo kwiMachining kunye neDynamic Balancing Weight Removal Unit Robot

Irobhothi yaseChenxuan: SDCX-RB08A3-1700

| Idatha esisiseko | |

| Uhlobo | I-SDCX-RB08A3-1700 |

| Inani lezembe | 6 |

| Ubuninzi bokhuselo | 3100mm |

| Ukumisa ukuphindaphinda (ISO 9283) | ±0.05mm |

| Ubunzima | 1134kg |

| Ukuhlelwa kokhuseleko lwerobhothi | Umgangatho wokhuseleko, IP65 / IP67isihlahla esingaphakathi(IEC 60529) |

| Ukuxhoma indawo | Isilingi, i-engile evumelekileyo yotyekelo ≤ 0º |

| Ukugqitywa komphezulu, ipeyinti | Isakhelo esisisiseko: esimnyama (RAL 9005) |

| Ubushushu obugciniwe | |

| Ukusebenza | 283 K ukuya kuma-328 K (0 °C ukuya +55 °C) |

| Ukugcinwa kunye nokuthutha | 233 K ukuya ku-333 K (-40 °C ukuya +60 °C) |

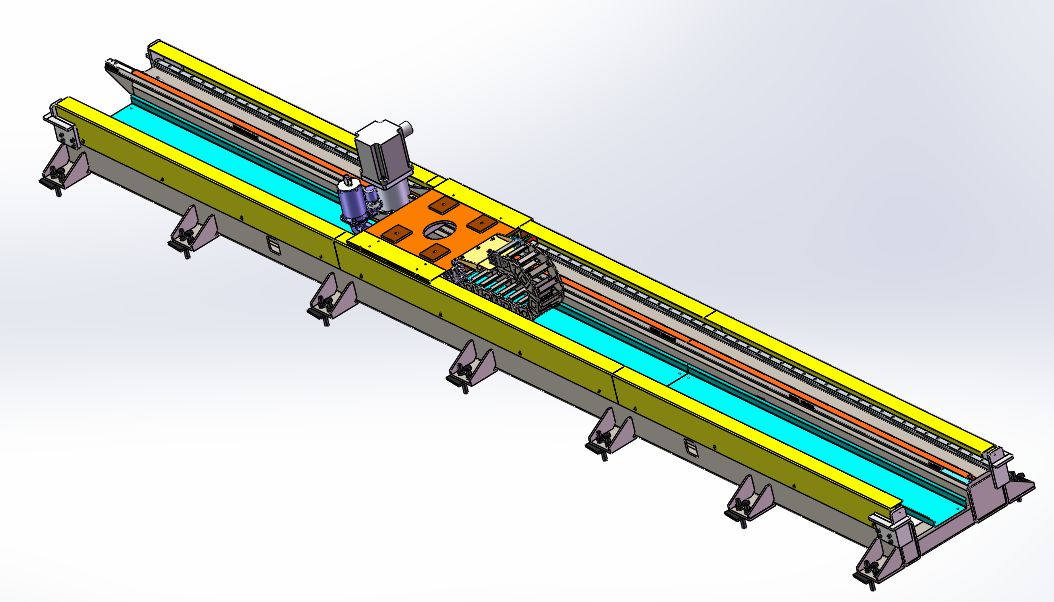

Ukuqaliswa kwe-Robot Travel Axis

Isakhiwo siqulunqwe ngerobhothi edibeneyo, i-servo motor drive kunye ne-pinion kunye ne-rack drive, ukwenzela ukuba i-robot ikwazi ukwenza ukunyakaza kwe-rectilinear ngasemva naphambili. Iyawuqonda umsebenzi werobhothi enye esebenza ngezixhobo zoomatshini abaninzi kunye nezixhobo zokubamba kwizikhululo ezininzi kwaye inokonyusa ukhuselo lokusebenza kweerobhothi ezidibeneyo;

Umkhondo wokuhamba usebenzisa isiseko esidityanisiweyo ngemibhobho yentsimbi kwaye iqhutywa yi-servo motor, ipinion kunye ne-rack drive, ukunyusa ukugubungela ukusebenza kwerobhothi edibeneyo kunye nokuphucula ngokufanelekileyo izinga lokusetyenziswa kwerobhothi;

Umzila wokuhamba ufakwe phantsi;

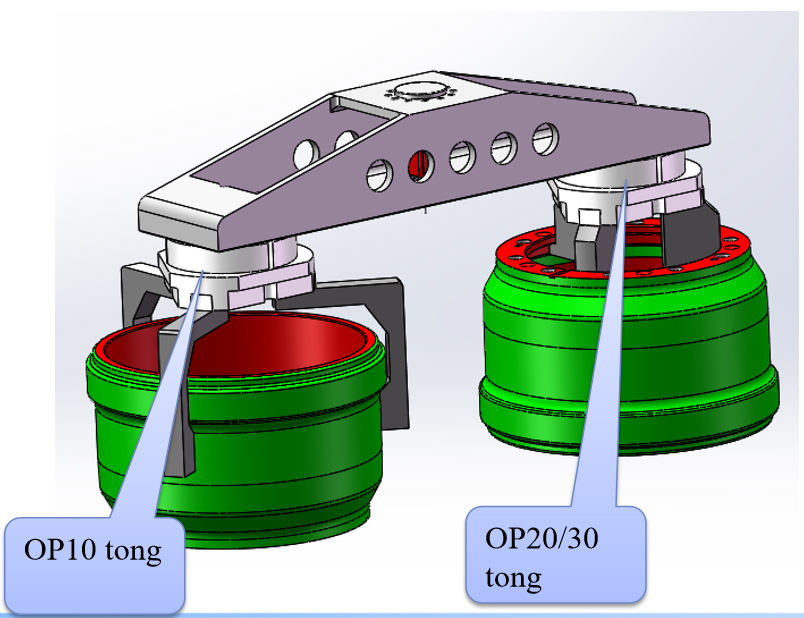

Ukuqaliswa kweetoni zokulayisha kunye neerobhothi ezingenanto

Inkcazo:

1. Ngokweempawu zale ndawo, sithatha umphezulu wamaza wangaphandle oneenzipho ezintathu;

2. Umatshini uxhotyiswe nge-sensor yokubona indawo kunye ne-sensor yoxinzelelo ukuze ibone ukuba i-clamping status kunye noxinzelelo lwamalungu aqhelekileyo;

3. Umtshini uxhotyiswe nge-pressurizer, kwaye i-workpiece ayiyi kuwela ngexesha elifutshane kwimeko yokungaphumeleli kwamandla kunye nokucinywa kwegesi yesekethe enkulu yomoya;

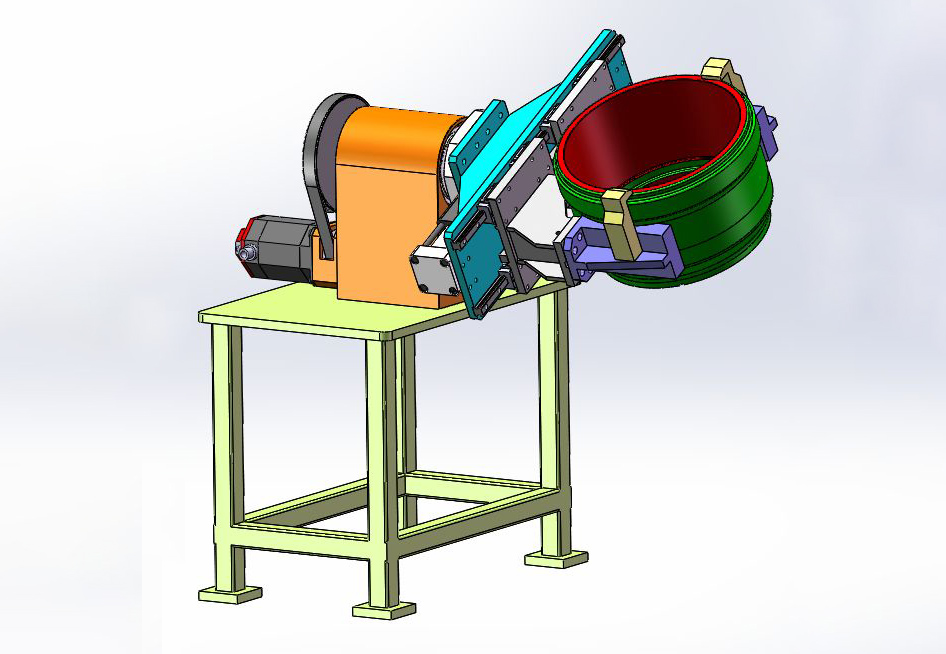

Ukwaziswa koMatshini wokuZiqengqela ngaphezulu

Inkcazo:

Isixhobo senziwe ngesakhelo esisisigxina, indibano yesiseko sokuxhasa kunye nendibano yetong ye-pneumatic. Inomsebenzi wokuchasana nokulahla emva kokunqanyulwa komoya, kwaye inokuqonda i-180 ° roll over of the line workpieces;

Intshayelelo kwibhentshi yokukhangela indawo yezandla

Inkcazo:

1. Cwangcisa iisampulu ezahlukeneyo zesampulu ezingaqhelekanga kwizigaba ezahlukeneyo zemveliso, ezinokongamela ngempumelelo umlinganiselo we-intanethi;

2. Imiyalelo yokuSetyenziswa: I-manipulator iya kubeka i-workpiece kwindawo yokubeka kwindawo yokujonga ibhentshi ngokwe-frequency iseti ngesandla, kwaye ikhawuleze isibane esibomvu. Umhloli uya kucinezela iqhosha ukuthutha i-workpiece kwindawo yokukhusela ngaphandle kokukhusela, akhuphe i-workpiece yokulinganisa kwaye ayibuyisele kwi-roller bed emva kokulinganisa;

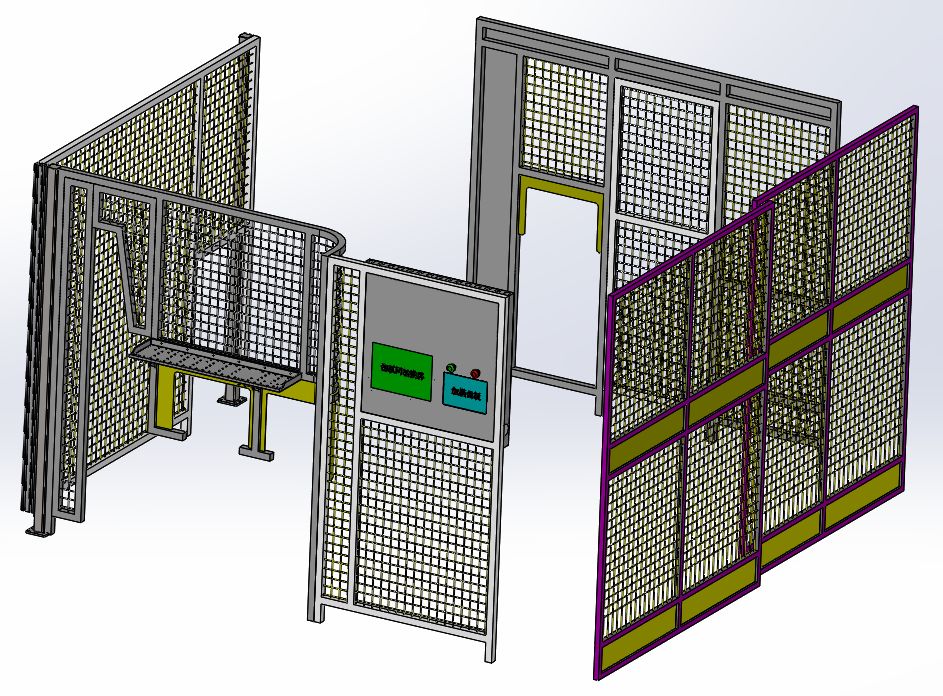

Amacandelo akhuselayo

Iqulunqwe ngeprofayili ye-aluminium elula (40 × 40) + i-mesh (50 × 50), kunye nesikrini sokuchukumisa kunye neqhosha lokumisa likaxakeka linokuhlanganiswa kumacandelo akhuselayo, ukudibanisa ukhuseleko kunye ne-aesthetics.

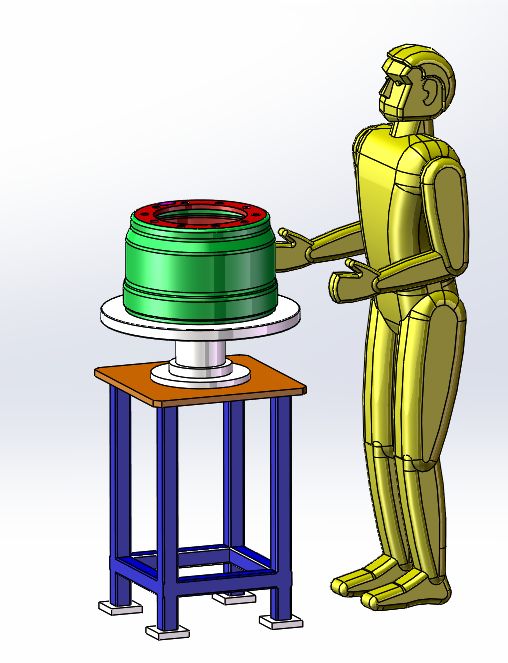

Intshayelelo kwiSikhululo sokuHlola ukulungisa ipeyinti

Inkcazo:

Isixhobo senziwe ngesakhelo esisisigxina kunye ne-turntable. Abasebenzi baphakamisa iimveliso ezigqityiweyo kwi-turntable, bajikelezisa i-turntable, bajonge ukuba kukho ama-bumps, ama-scratches kunye nezinye izinto, kunye nokulungiswa kwangethuba iziphene eziqhumayo kunye nomphezulu wepeyinti;