Isishwankathelo seProjekthi

1. Inkqubo yeMveliso

Iiseti ezingama-600/ngosuku (i-117/118 ithwele i-pedestral)

2. Iimfuno zomgca wokucubungula:

1) Iziko lomatshini le-NC lilungele umgca wemveliso ozenzekelayo;

2) I-Hydraulic frock clamp;

3) Ukulayishwa okuzenzekelayo kunye nesixhobo esingenanto kunye nesixhobo sokuhambisa;

4) Itekhnoloji yokucubungula ngokubanzi kunye nexesha lomjikelo wokucubungula;

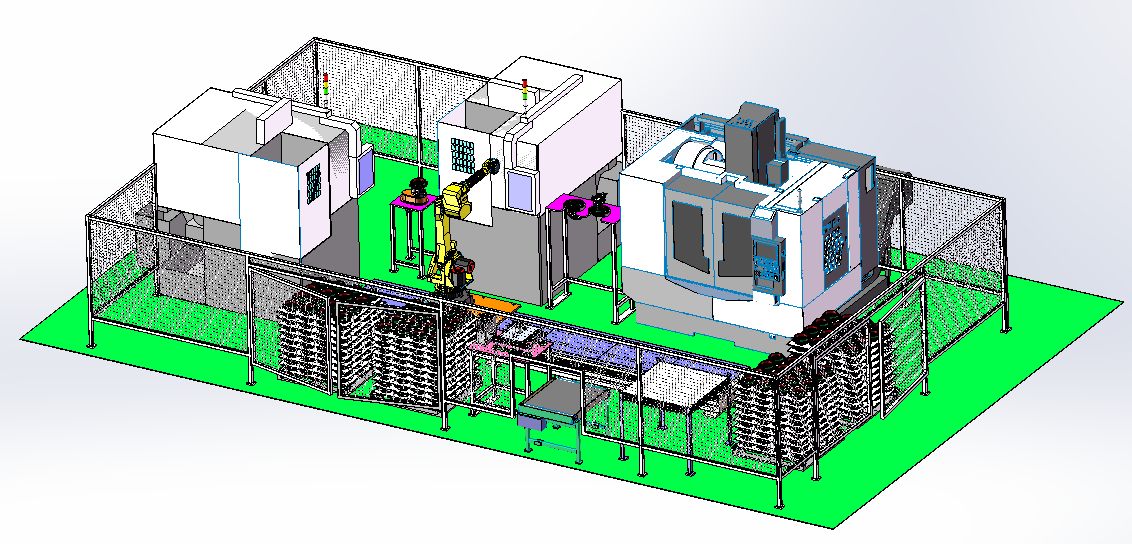

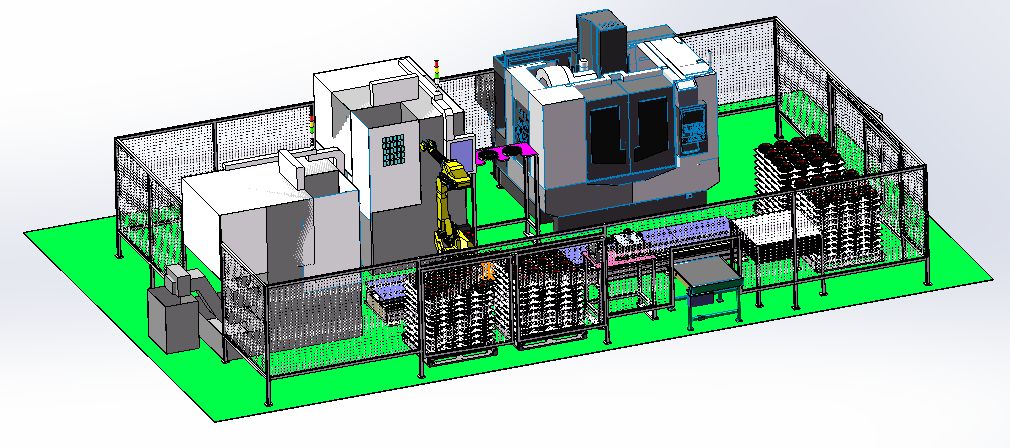

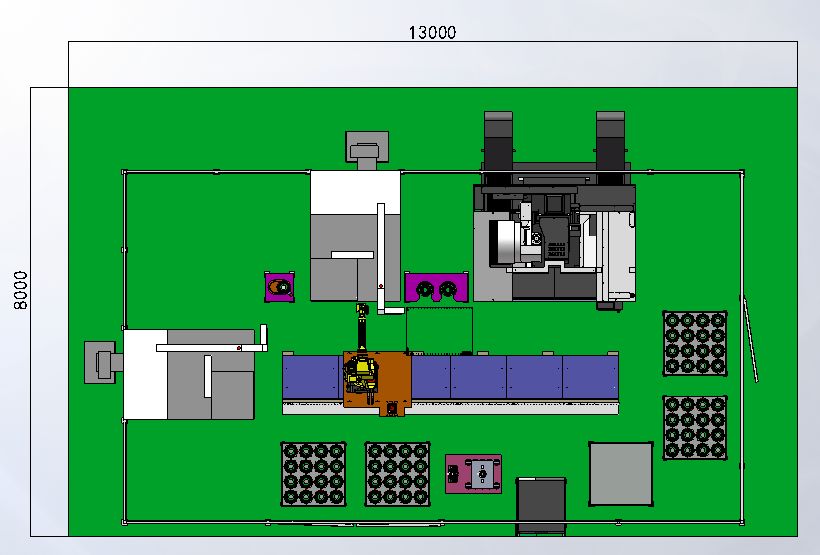

Uyilo lweeNdlela zeMveliso

Uyilo lweeNdlela zeMveliso

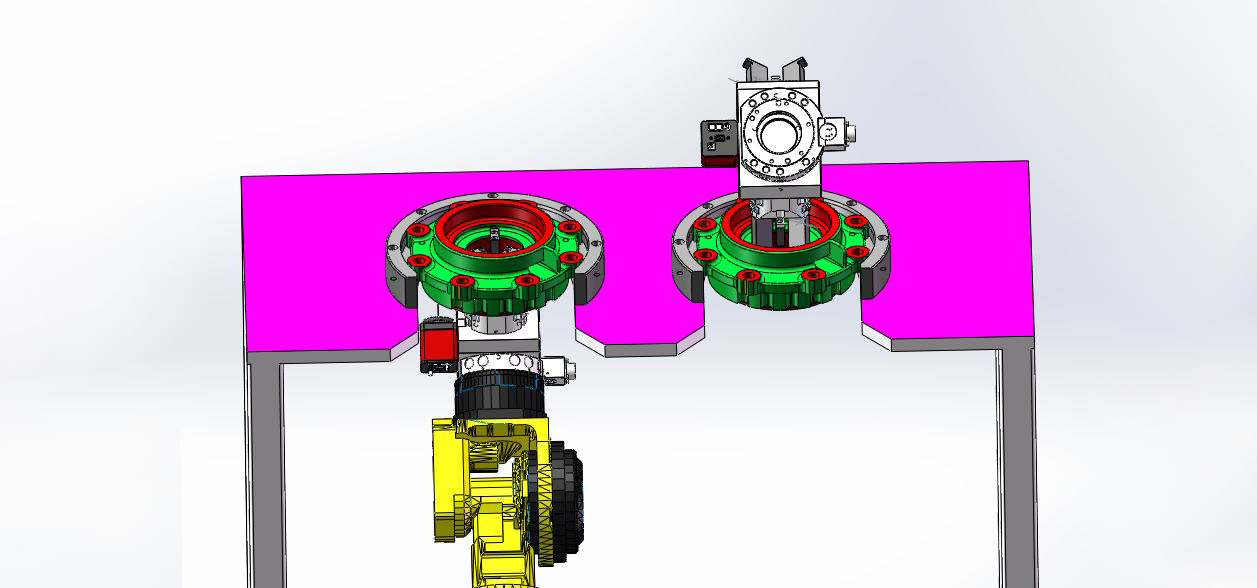

Intshayelelo yeentshukumo zeRobhothi:

1. Beka ngesandla iibhaskithi ezenziwe ngokurhabaxa kwaye ubeke phezu kwetafile yokulayisha (Ukulayisha iitafile No. 1 kunye neNo. 2) kwaye ucinezele iqhosha ukuze uqinisekise;

2. I-robot ihambela kwi-tray ye-No. 1 itafile yokulayisha, ivula inkqubo yombono, ibambe kwaye ihambise iCandelo A kunye ne-B ngokulandelanayo kwisikhululo sokujonga i-angular ukulinda umyalelo wokulayisha;

3. Umyalelo wokulayisha uthunyelwa ngesikhululo sokuqaphela i-angular. Irobhothi ibeka isiqwenga se-1 kwindawo yokubeka i-turntable. Jikelezisa i-turntable kwaye uqale inkqubo yokuqaphela i-angular, unqume indawo ye-angular, yeka i-turntable kwaye ugqibe ukuqatshelwa kwe-angular ye-1 piece;

4. Inkqubo yokuqaphela i-angular ithumela umyalelo ongenanto, kwaye i-robot ithatha isiqwenga se-1 kwaye ibeke i-No. I-turntable iyajikeleza kwaye inkqubo yokuqaphela i-angular iqala ukumisela indawo ye-angular. I-turntable iyayeka kunye nokuqatshelwa kwe-angular ye-2 piece igqityiwe, kwaye umyalelo ongenanto uthunyelwa;

5. I-robot ifumana umyalelo ongenanto weNombolo ye-1 ye-lathe ethe nkqo, ihambela kwindawo yokulayisha kunye ne-blanking yeNombolo ye-1 ye-lathe ethe nkqo yokuvala izinto kunye nokulayisha. Emva kokuba isenzo sigqityiwe, umjikelo womatshini womatshini omnye we-lathe ethe nkqo uyaqala;

6. Irobhothi ithatha iimveliso ezigqityiweyo ngeNombolo ye-1 ye-lathe ethe nkqo kwaye iyibeke kwindawo yeNombolo ye-1 kwi-workpiece roll-over table;

7. I-robot ifumana umyalelo ongenanto weNombolo ye-2 ye-lathe ethe nkqo, ihambela kwindawo yokulayishwa kunye ne-blanking yeNo.

8. Irobhothi ithatha iimveliso ezigqityiweyo ngeNombolo ye-2 ye-lathe ethe nkqo kwaye iyibeke kwindawo yeNombolo yesi-2 kwitafile yokuqengqeleka;

9. Irobhothi ilinda umyalelo ongenanto ovela kumatshini othe nkqo;

10. I-vertical machining ithumela umyalelo ongenanto, kwaye i-robot ishukuthela kwindawo yokulayisha kunye ne-blanking ye-vertical machining, ibambe kwaye ihambise i-workpieces ye-Nombolo ye-1 kunye ne-No. Irobhothi ishukuthela kwitafile yokuqengqeleka ukuze ibambe kwaye ithumele iNombolo ye-1 kunye neNombolo ye-2 kumatshini wokupakisha ngokuthe nkqo kunye nezikhundla zokuvala ngokulandelelana, kwaye ibeka iNombolo ye-1 kunye neNombolo yee-workpieces kwindawo yokubeka indawo yeNombolo ye-1 kunye neNombolo ye-2 ye-clamp ye-hydraulic ngokulandelelana ukugqiba ukulayisha umatshini wokumisa ngokuthe nkqo. Irobhothi iphuma kumgama wokhuseleko womatshini othe nkqo kwaye iqala umjikelo omnye wokucubungula;

11. I-robot ihambela kwiNombolo ye-1 yokulayisha i-tray kwaye ilungiselela ukuqaliswa kweprogram ye-secondary cycle program;

Inkcazo:

1. Irobhothi ithatha iziqwenga ezili-16 (umaleko omnye) kwitreyi yokulayisha. Irobhothi iya kuthatha indawo yetong yekomityi yokufunxa kwaye ibeke ipleyiti yokwahlula kwindawo yokugcina okwexeshana;

2. Irobhothi ipakisha iziqwenga ezili-16 (umaleko omnye) kwitreyi engenanto. Irobhothi kufuneka ibuyisele itong yekomityi yokufunxa kube kanye, kwaye ibeke ipleyiti yolwahlulo kumphezulu wokwahlula amalungu asuka kwingobozi yokugcina yethutyana;

3. Ngokwezandi zokuhlola, qinisekisa ukuba irobhothi ibeka inxalenye kwitafile yesampulu yesandla;

| 1 | Ithayimthebhile yomjikelo womatshini | ||||||||||||||

| 2 | Umthengi | Izinto eziphathekayo | QT450-10-GB/T1348 | Imodeli yesixhobo somatshini | Uvimba onguNomb. | ||||||||||

| 3 | Igama lemveliso | 117 Ukuthwala isitulo | Umzobo inombolo. | DZ90129320117 | Umhla wokulungiselela | 2020.01.04 | Ilingiselelwe ngu | ||||||||

| 4 | Inyathelo lenkqubo | Imela Nomb. | umxholo womatshini | Igama lesixhobo | Ukusika Ububanzi | Ukusika isantya | Isantya sokujikeleza | Ukutya ngokwenguquko nganye | Ukutya ngesixhobo somatshini | Inani lokusikwa | Inkqubo nganye | ixesha Machining | Ixesha lokungenzi nto | Ixesha elijikelezayo le-axis emine | Ixesha lokutshintsha isixhobo |

| 5 | Hayi. | Hayi. | Ukuchithwa | Izixhobo | D mm | n | R pm | mm/Rev | mm/Mzu | Amaxesha | mm | Isiqendu | Isiqendu | Isiqendu | |

| 6 |  | ||||||||||||||

| 7 | 1 | T01 | Milling enyuka umngxuma umphezulu | Ububanzi be-40-face milling cutter | 40.00 | 180 | 1433 | 1.00 | 1433 | 8 | 40.0 | 13.40 | 8 | 4 | |

| 8 | Gqoka i-DIA i-17 imingxuma yokufaka | I-DIA 17 I-DRILL EDIDIYWEYO | 17.00 | 100 | 1873 | 0.25 | 468 | 8 | 32.0 | 32.80 | 8 | 4 | |||

| 9 | T03 | DIA 17 umngxuma ngasemva chamfering | Reverse chamfering cutter | 16.00 | 150 | 2986 | 0.30 | 896 | 8 | 30.0 | 16.08 | 16 | 4 | ||

| 10 | Inkcazo: | Ixesha lokusika: | 62 | Isibini | Ixesha lokubamba nge-fixture kunye nokulayisha kunye nezinto ezingenanto: | 30.00 | Isibini | ||||||||

| 11 | Ixesha elincedisayo: | 44 | Isibini | Iiyure zomsebenzi zizonke: | 136.27 | Isibini | |||||||||

| 1 | Ithayimthebhile yomjikelo womatshini | |||||||||||||||||

| 2 | Umthengi | Izinto eziphathekayo | QT450-10-GB/T1348 | Imodeli yesixhobo somatshini | Uvimba onguNomb. | |||||||||||||

| 3 | Igama lemveliso | 118 Ukuthwala isihlalo | Umzobo inombolo. | DZ90129320118 | Umhla wokulungiselela | 2020.01.04 | Ilingiselelwe ngu | |||||||||||

| 4 | Inyathelo lenkqubo | Imela Nomb. | umxholo womatshini | Igama lesixhobo | Ukusika Ububanzi | Ukusika isantya | Isantya sokujikeleza | Ukutya ngokwenguquko nganye | ukondla ngesixhobo somatshini | Inani lokusikwa | Inkqubo nganye | ixesha Machining | Ixesha lokungenzi nto | Ixesha elijikelezayo le-axis emine | Ixesha lokutshintsha isixhobo | |||

| 5 | Hayi. | Hayi. | Ukuchithwa | Izixhobo | D mm | n | R pm | mm/Rev | mm/Mzu | Amaxesha | mm | Isiqendu | Isiqendu | Isiqendu | ||||

| 6 |

| |||||||||||||||||

| 7 | 1 | T01 | Milling enyuka umngxuma umphezulu | Ububanzi be-40-face milling cutter | 40.00 | 180 | 1433 | 1.00 | 1433 | 8 | 40.0 | 13.40 | 8 | 4 | ||||

| 8 | T02 | Gqoka i-DIA i-17 imingxuma yokufaka | I-DIA 17 I-DRILL EDIDIYWEYO | 17.00 | 100 | 1873 | 0.25 | 468 | 8 | 32.0 | 32.80 | 8 | 4 | |||||

| 9 | T03 | DIA 17 umngxuma ngasemva chamfering | Reverse chamfering cutter | 16.00 | 150 | 2986 | 0.30 | 896 | 8 | 30.0 | 16.08 | 16 | 4 | |||||

| 10 | Inkcazo: | Ixesha lokusika: | 62 | Isibini | Ixesha lokubamba nge-fixture kunye nokulayisha kunye nezinto ezingenanto: | 30.00 | Isibini | |||||||||||

| 11 | Ixesha elincedisayo: | 44 | Isibini | Iiyure zomsebenzi zizonke: | 136.27 | Isibini | ||||||||||||

| 12 | ||||||||||||||||||

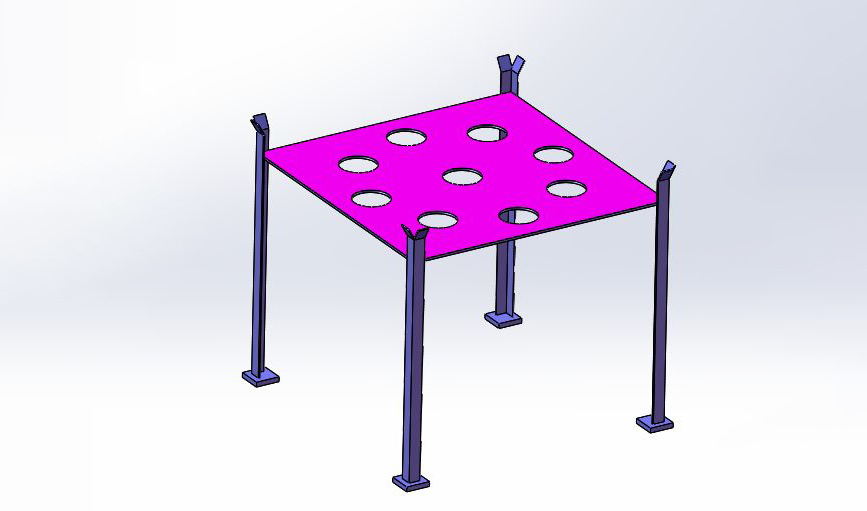

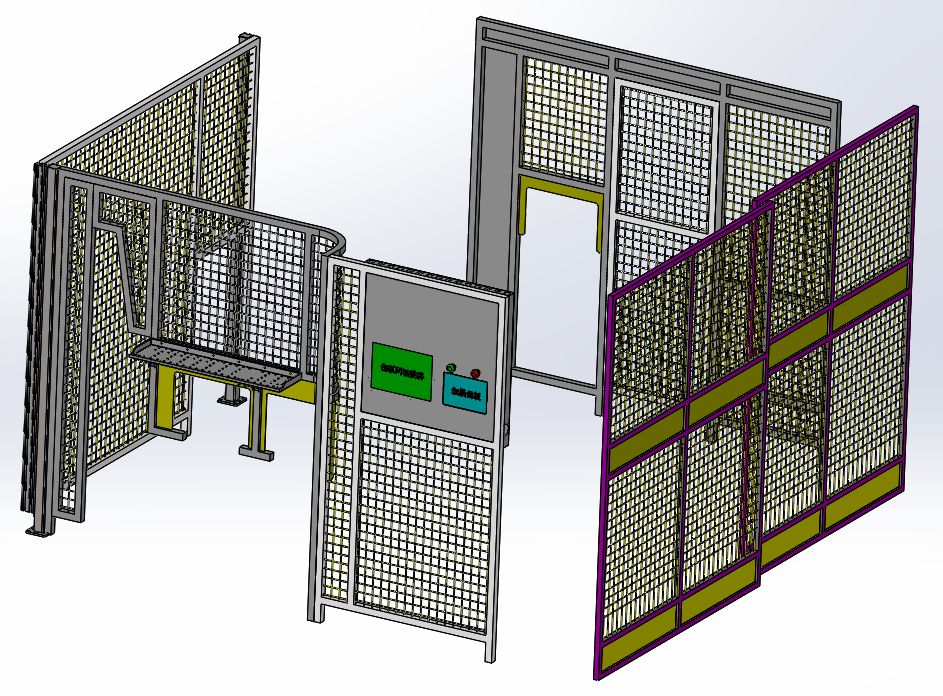

Indawo yokugubungela umgca wemveliso

Ukwaziswa kwamacandelo aphambili asebenzayo omgca wemveliso

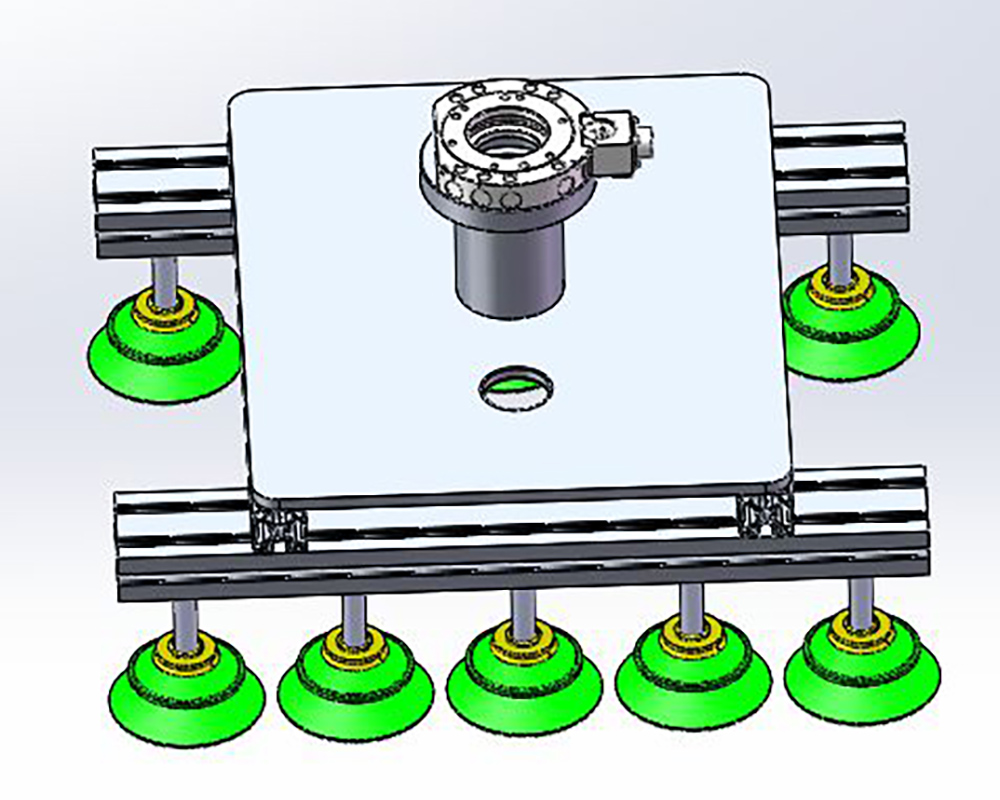

Ukuqaliswa kwenkqubo yokulayisha kunye nokuvala

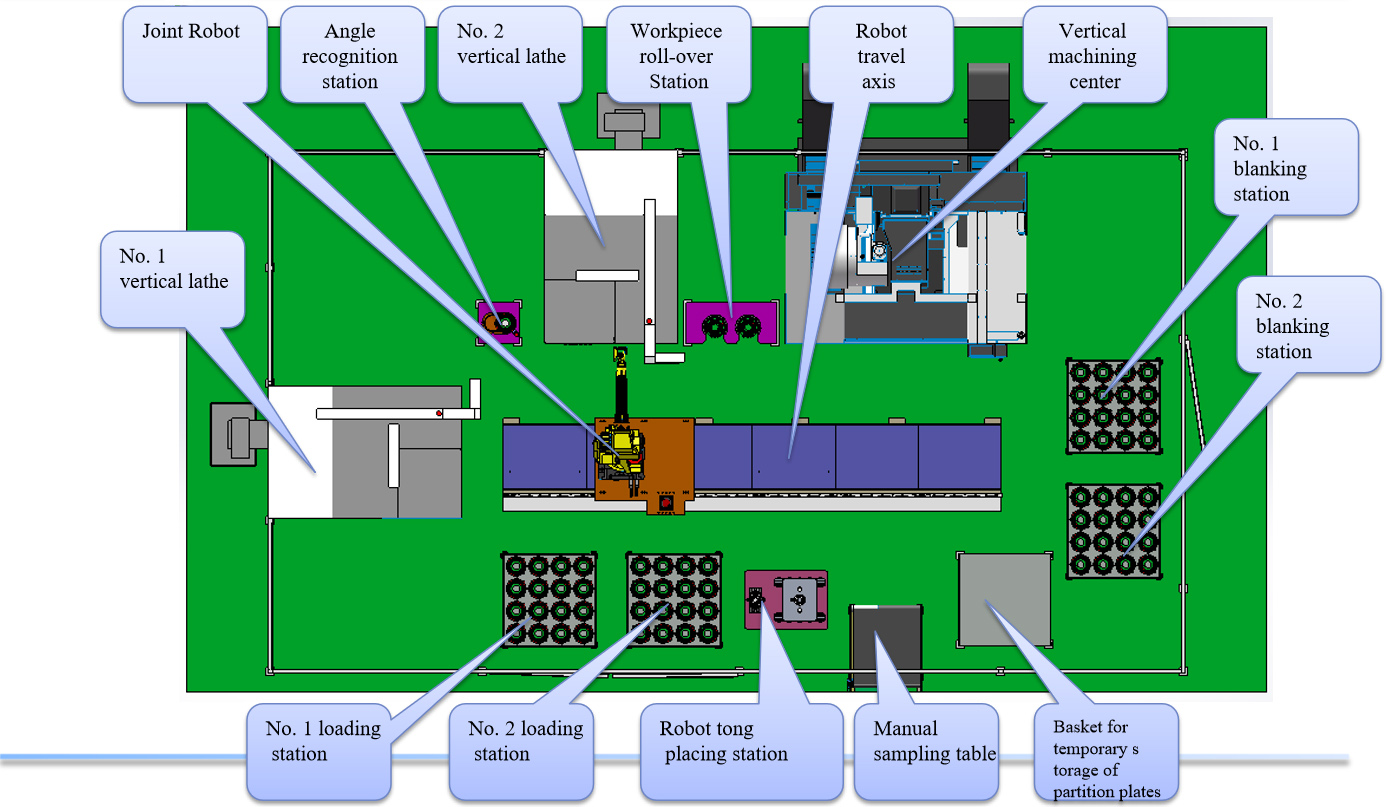

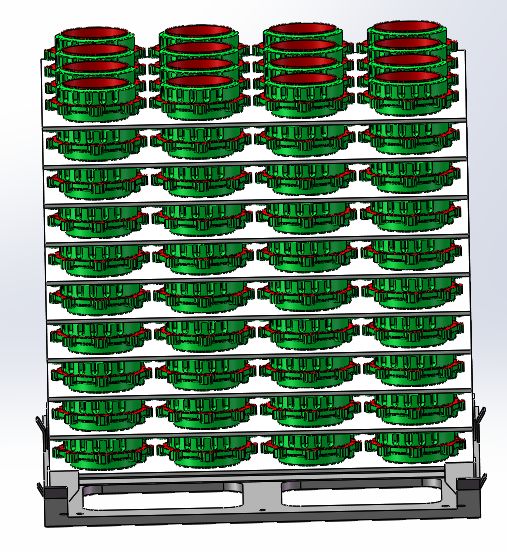

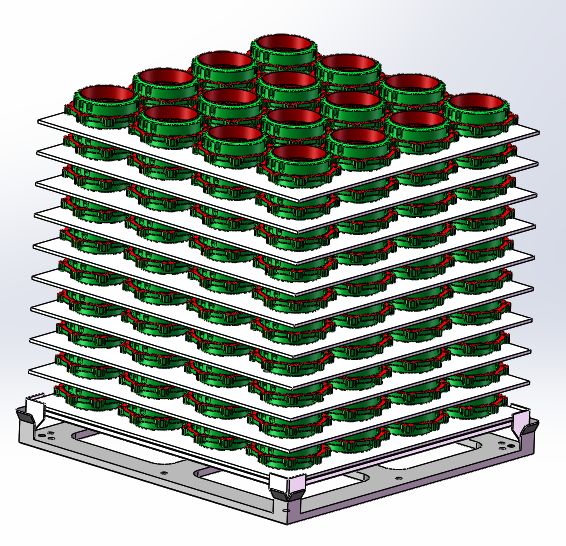

Izixhobo zokugcina umgca wemveliso oluzenzekelayo kwesi sikimu yile: Itreyi epakishwe (ubuninzi beziqwenga eziza kupakishwa kwitreyi nganye ziya kuthethathethwana nomthengi), kunye nokubekwa kwendawo yokusebenzela kwitreyi kuya kumiselwa emva kokubonelela ngomzobo we-3D we-workpiece engenanto okanye eyona nto.

1. Abasebenzi bapakisha iindawo ezicwangcisiweyo ngokucokisekileyo kwi-tray yezinto eziphathekayo (njengoko kuboniswe kumfanekiso) kwaye bafake i-forklift kwindawo echongiweyo;

2. Emva kokutshintsha i-tray ye-forklift, cinezela ngesandla iqhosha ukuze uqinisekise;

3. Irobhothi ibamba i-workpiece ukwenza umsebenzi wokulayisha;

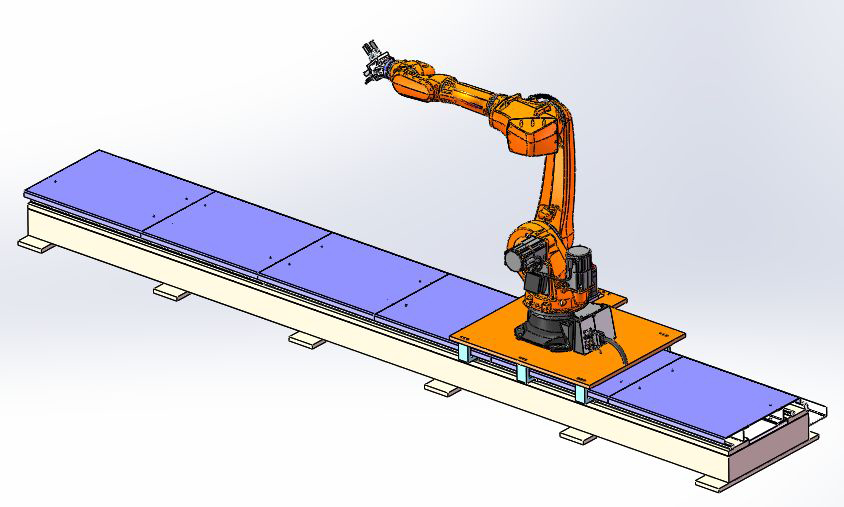

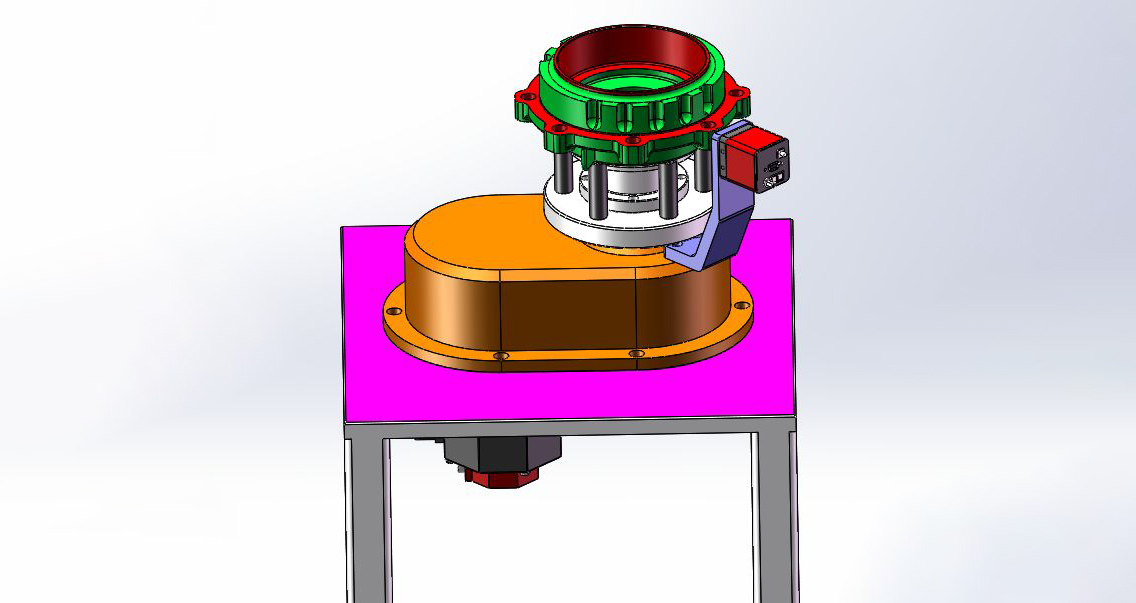

Ukuqaliswa kwe-Robot Travel Axis

Isakhiwo siqulunqwe ngerobhothi edibeneyo, i-servo motor drive kunye ne-pinion kunye ne-rack drive, ukwenzela ukuba i-robot ikwazi ukwenza ukunyakaza kwe-rectilinear ngasemva naphambili. Iyawuqonda umsebenzi werobhothi enye esebenza ngezixhobo zoomatshini abaninzi kunye nezixhobo zokubamba kwizikhululo ezininzi kwaye inokonyusa ukhuselo lokusebenza kweerobhothi ezidibeneyo;

Umkhondo wokuhamba usebenzisa isiseko esidityanisiweyo ngemibhobho yentsimbi kwaye iqhutywa yi-servo motor, ipinion kunye ne-rack drive, ukunyusa ukugubungela ukusebenza kwerobhothi edibeneyo kunye nokuphucula ngokufanelekileyo izinga lokusetyenziswa kwerobhothi; Umzila wokuhamba ufakwe phantsi;

Irobhothi yaseChenxuan:SDCX-RB500

| Idatha esisiseko | |

| Uhlobo | SDCX-RB500 |

| Inani lezembe | 6 |

| Ubuninzi bokhuselo | 2101mm |

| Ukumisa ukuphindaphinda (ISO 9283) | ±0.05mm |

| Ubunzima | 553kg |

| Ukuhlelwa kokhuseleko lwerobhothi | Umgangatho wokhuseleko, IP65 / IP67isihlahla esingaphakathi(IEC 60529) |

| Ukuxhoma indawo | Isilingi, i-engile evumelekileyo yotyekelo ≤ 0º |

| Ukugqitywa komphezulu, ipeyinti | Isakhelo esisisiseko: esimnyama (RAL 9005) |

| Ubushushu obugciniwe | |

| Ukusebenza | 283 K ukuya kuma-328 K (0 °C ukuya +55 °C) |

| Ukugcinwa kunye nokuthutha | 233 K ukuya ku-333 K (-40 °C ukuya +60 °C) |

Ngoluhlu olubanzi lwe-domain eshukumayo ngasemva nasezantsi kwirobhothi, ukuba yimodeli ekwaziyo ukunyuswa ngokuphakanyiswa kwesilingi. Ngenxa yokuba ububanzi becala berobhothi buncitshisiwe ukuya kumda, kunokwenzeka ukuba ifakwe ngokusondeleyo kwirobhothi ekufutshane, i-clamp, okanye i-workpiece. Intshukumo yesantya esiphezulu ukusuka kwindawo yokulinda ukuya kwindawo yokusebenza kunye nokumiswa ngokukhawuleza ngexesha lentshukumo yomgama omfutshane.

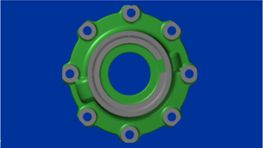

Ukulayishwa kwerobhothi ekrelekrele kunye nomatshini ongenanto

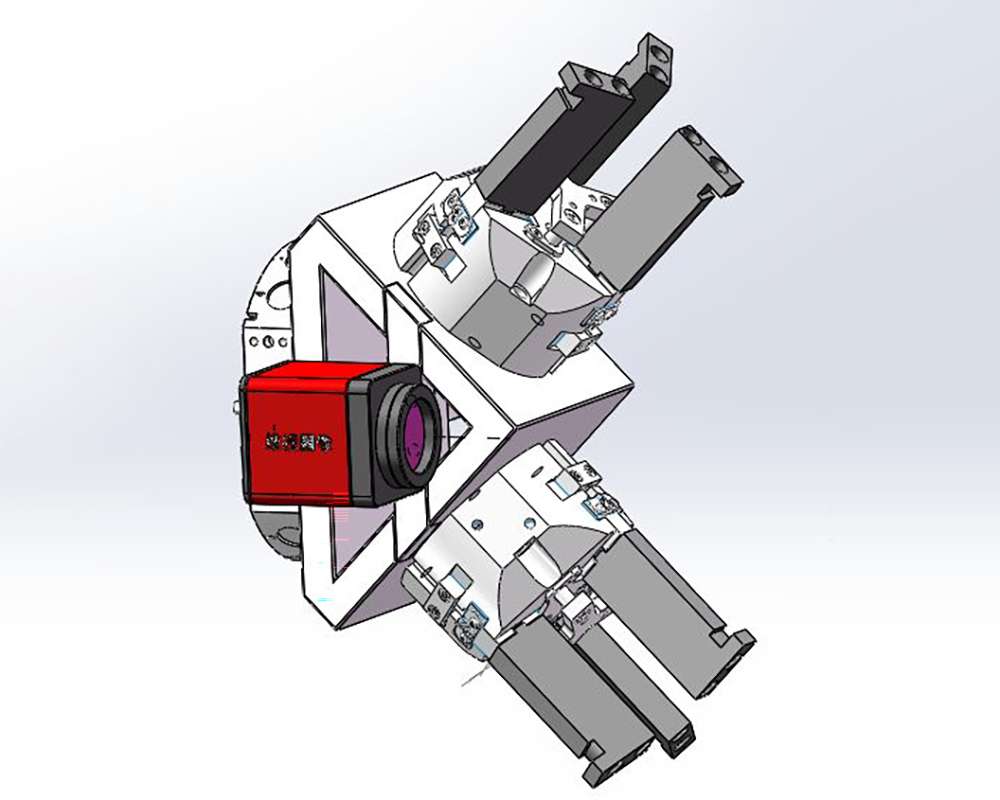

Indlela yokwahlulahlula ipleyiti yerobhothi

Inkcazo:

1. Ukuqwalasela iimpawu zale nxalenye, sisebenzisa iindlela ezintathu ezixhasayo zangaphandle ukulayisha kunye nokukhupha izinto eziphathekayo, ezinokuqonda ukujika ngokukhawuleza kwamacandelo kwisixhobo somatshini;

2. Umatshini uxhotyiswe nge-sensor yokubona indawo kunye ne-sensor yoxinzelelo ukuze ibone ukuba i-clamping status kunye noxinzelelo lwamalungu aqhelekileyo;

3. Umtshini uxhotyiswe nge-pressurizer, kwaye i-workpiece ayiyi kuwela ngexesha elifutshane kwimeko yokungaphumeleli kwamandla kunye nokucinywa kwegesi yesekethe enkulu yomoya;

4. Isixhobo sokutshintsha isandla samkelwe. Ukutshintsha indlela yetong kunokugqiba ngokukhawuleza ukubethelwa kwezixhobo ezahlukeneyo.

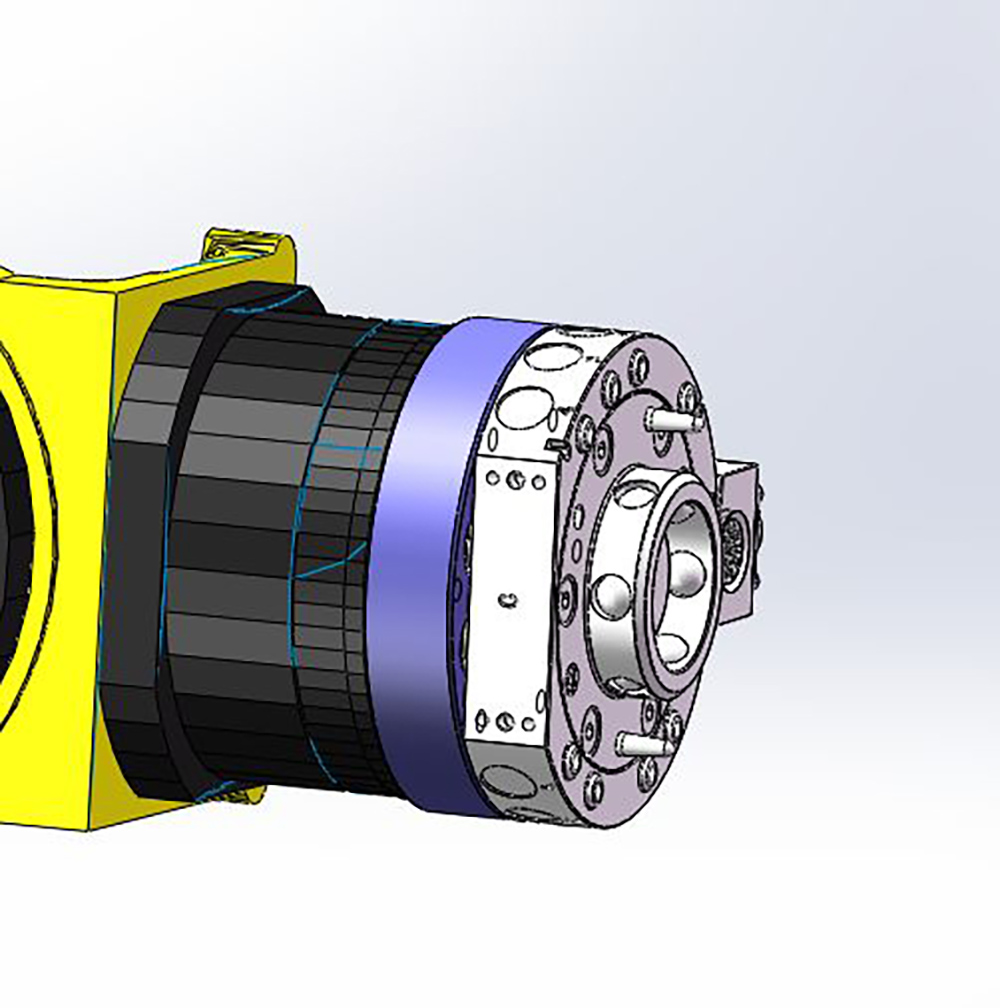

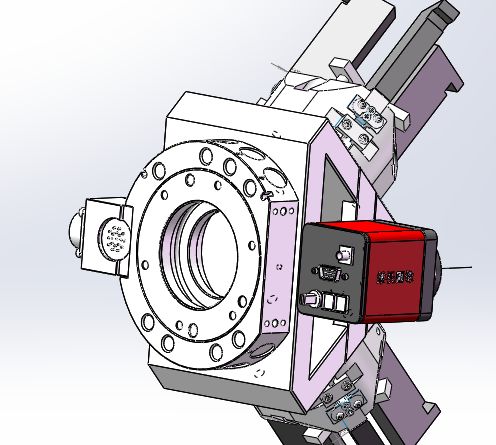

Ukwaziswa kwesixhobo soTshintsho lweTong

Isixhobo esichanekileyo sokutshintsha itong sisetyenziselwa ukutshintsha ngokukhawuleza iitoni zerobhothi, iziphelo zesixhobo, kunye nezinye ii-actuator. Ukunciphisa ixesha lokungenzi nto kwimveliso kunye nokwandisa ukuguquguquka kwerobhothi, eboniswe njenge:

1. Vula kwaye uqinise uxinzelelo lomoya;

2. Iimodyuli ezahlukeneyo zamandla, ulwelo kunye negesi zingasetyenziswa;

3. Ukucwangciswa okusemgangathweni kunokukhawuleza ukudibanisa nomthombo womoya;

4. Ii-arhente ezikhethekileyo ze-inshorensi zinokuthintela umngcipheko wokucinywa kwerhasi ngengozi;

5. Akukho mandla okusabela entwasahlobo; 6. Isebenza kwibala lokuzenzekelayo;

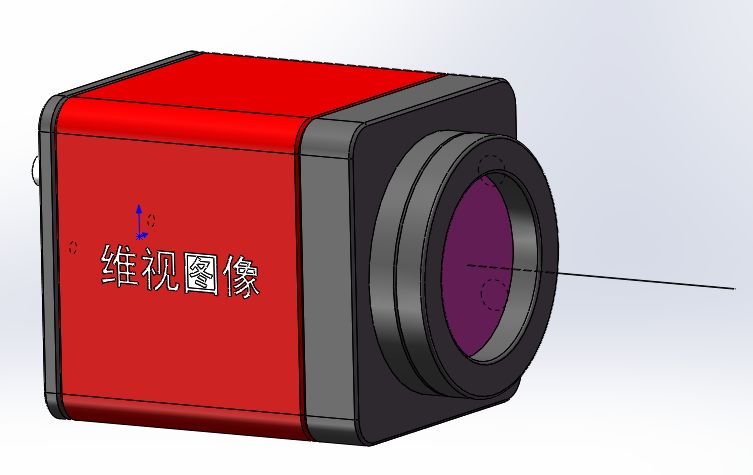

Intshayelelo kwiSistim yeMbono-yeKhamera yoShishino

1. Ikhamera ithatha umgangatho ophezulu weCCD kunye ne-CMDS chips, eneempawu zokulinganisa okuphezulu, uvakalelo oluphezulu, umlinganiselo ophezulu we-signal-to-frequency ratio, uluhlu olubanzi oluguquguqukayo, umgangatho obalaseleyo wokucinga kunye nokukwazi ukubuyisela umbala weklasi yokuqala;

2. Ikhamera yendawo yekhamera ineendlela ezimbini zokudlulisa idatha: I-GIGabit Ethernet (GigE) interface kunye ne-USB3.0 interface;

3. Ikhamera inesakhiwo esincinci, imbonakalo encinci, ilula kwaye ifakwe. Isantya esiphezulu sothumelo, isakhono esinamandla sokuchasana nokuphazamiseka, imveliso ezinzileyo yomfanekiso ophezulu; Isebenza ekufundeni ikhowudi, ukufumanisa isiphene, i-DCR kunye nokuqatshelwa kwepateni; Ikhamera yombala inamandla okubuyisela umbala, ifanelekile kwiimeko ezinemfuno ephezulu yokuqaphela umbala;

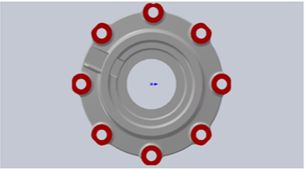

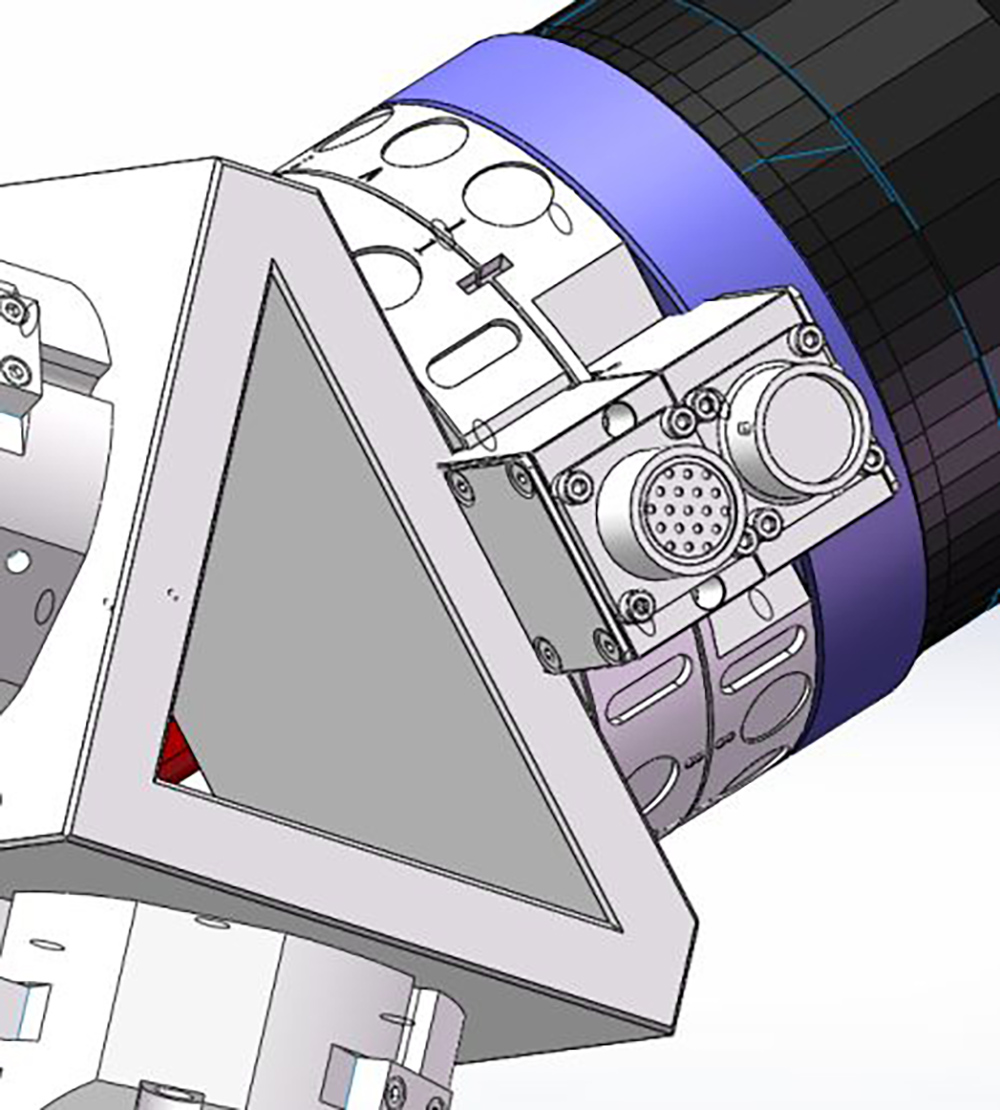

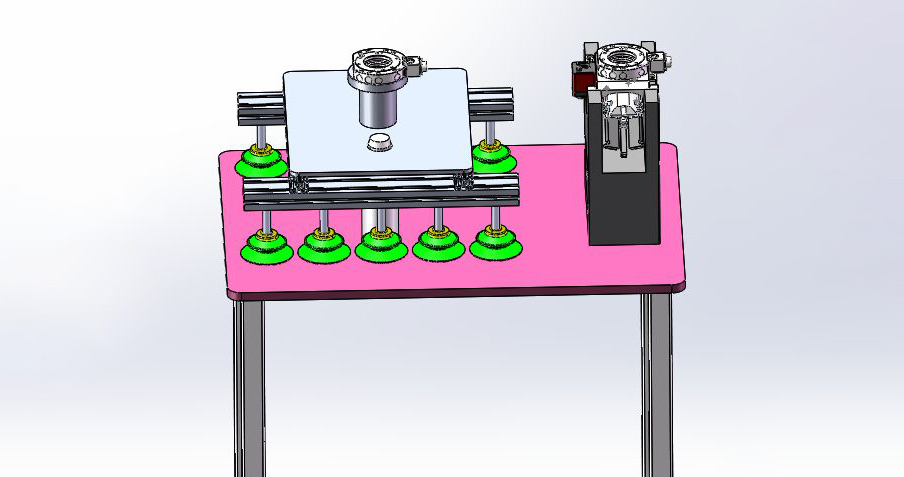

Ukuqaliswa kwe-Angular Automatic Recognition System

Umsebenzi Intshayelelo

1. I-robot ibamba i-workpieces ukusuka kwiibhasikithi zokulayisha kwaye ithumele kwindawo yokubeka i-turntable;

2. I-Turntable ijikeleza phantsi kwe-drive ye-servo motor;

3. Inkqubo yokubona (ikhamera ye-industrial) isebenza ukuchonga indawo ye-angular, kwaye i-turntable iyayeka ukujonga indawo efunekayo ye-angular;

4. Irobhothi ikhupha i-workpiece kwaye ibeke esinye isiqwenga sokuchonga i-angular;

Intshayelelo yeWorkpiece Roll-over Table

Isitishi esiqengqelekayo:

1. Irobhothi ithatha i-workpiece kwaye iyibeke kwindawo yokubeka kwitafile yokuqengqeleka (isikhululo sasekhohlo emfanekisweni);

2. Irobhothi ibamba i-workpiece ukusuka phezulu ukuze iqonde i-roller ye-workpiece;

Itheyibhile yokubeka irobhothi

Umsebenzi Intshayelelo

1. Emva kokuba uluhlu ngalunye lwamacandelo lulayishiwe, i-plate ye-partition plate iya kufakwa kwi-basket yesikhashana yokugcina iiplate zokwahlula;

2. Irobhothi inokutshintshwa ngokukhawuleza endaweni yekomityi yokufunxa ngesixhobo sokutshintsha ithoni kwaye isuse iipleyiti zokwahlula;

3. Emva kokuba iipleyiti zokwahlula zibekwe kakuhle, khulula itong yekomityi yokufunxa kwaye ubeke endaweni yetong yomoya ukuze uqhubeke nokulayisha kunye nezinto ezingenanto;

Ibhaskithi yokugcinwa kwexeshana kweepleyiti zokwahlula

Umsebenzi Intshayelelo

1. Ibhaskithi yethutyana yeepleyiti zokwahlula iyilwe kwaye icwangciswe njengoko iipleyiti zokwahlulahlula ukuze zilayishwe zirhoxiswa kuqala kwaye iipleyiti zokwahlulahlula zisetyenziswa kamva;

2. Iipleyiti zokwahlula zokulayisha zibekwe ngesandla kwaye azihambelani kakuhle. Emva kokuba ipleyiti yokwahlula ifakwe kwibhasikithi yokugcina yesikhashana, i-robot inokukhupha kwaye iyibeke kakuhle;

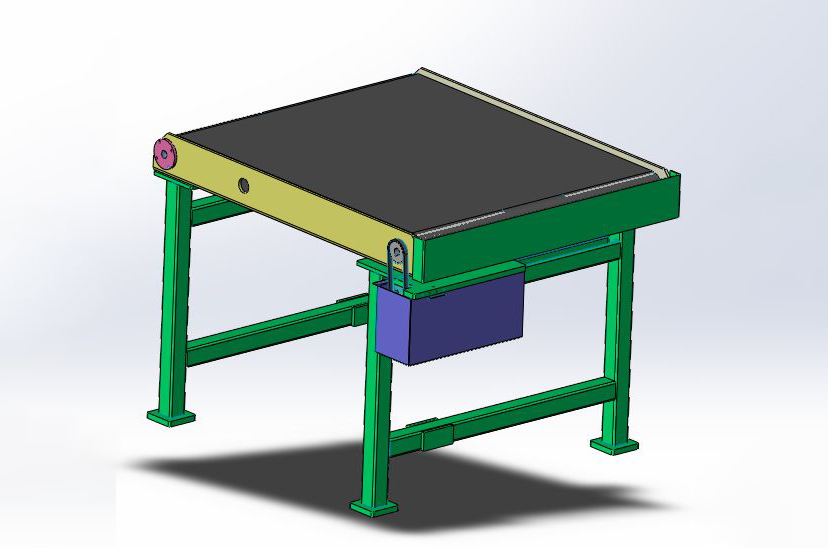

Itheyibhile yesampulu eyenziwe ngesandla

Inkcazo:

1. Cwangcisa iisampulu ezahlukeneyo zesampulu ezingaqhelekanga kwizigaba ezahlukeneyo zemveliso, ezinokongamela ngempumelelo umlinganiselo we-intanethi;

2. Imiyalelo yokuSetyenziswa: I-manipulator iya kubeka i-workpiece kwindawo emiselweyo kwitheyibhile yesampuli ngokwe-frequency set manually, kwaye ikhawuleze isibane esibomvu. Umhloli uya kucinezela iqhosha ukuthutha i-workpiece kwindawo yokukhusela ngaphandle kokukhusela, akhuphe i-workpiece yokulinganisa kwaye ayigcine ngokwahlukileyo emva kokulinganisa;

Amacandelo akhuselayo

Iqulunqwe ngeprofayili ye-aluminium elula (40 × 40) + i-mesh (50 × 50), kunye nesikrini sokuchukumisa kunye neqhosha lokumisa likaxakeka linokuhlanganiswa kumacandelo akhuselayo, ukudibanisa ukhuseleko kunye ne-aesthetics.

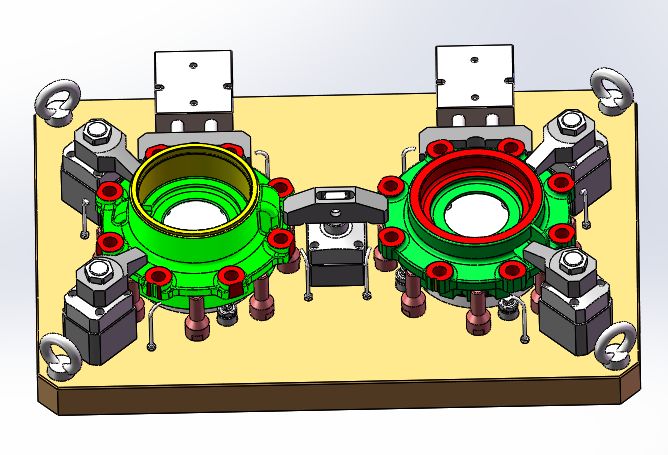

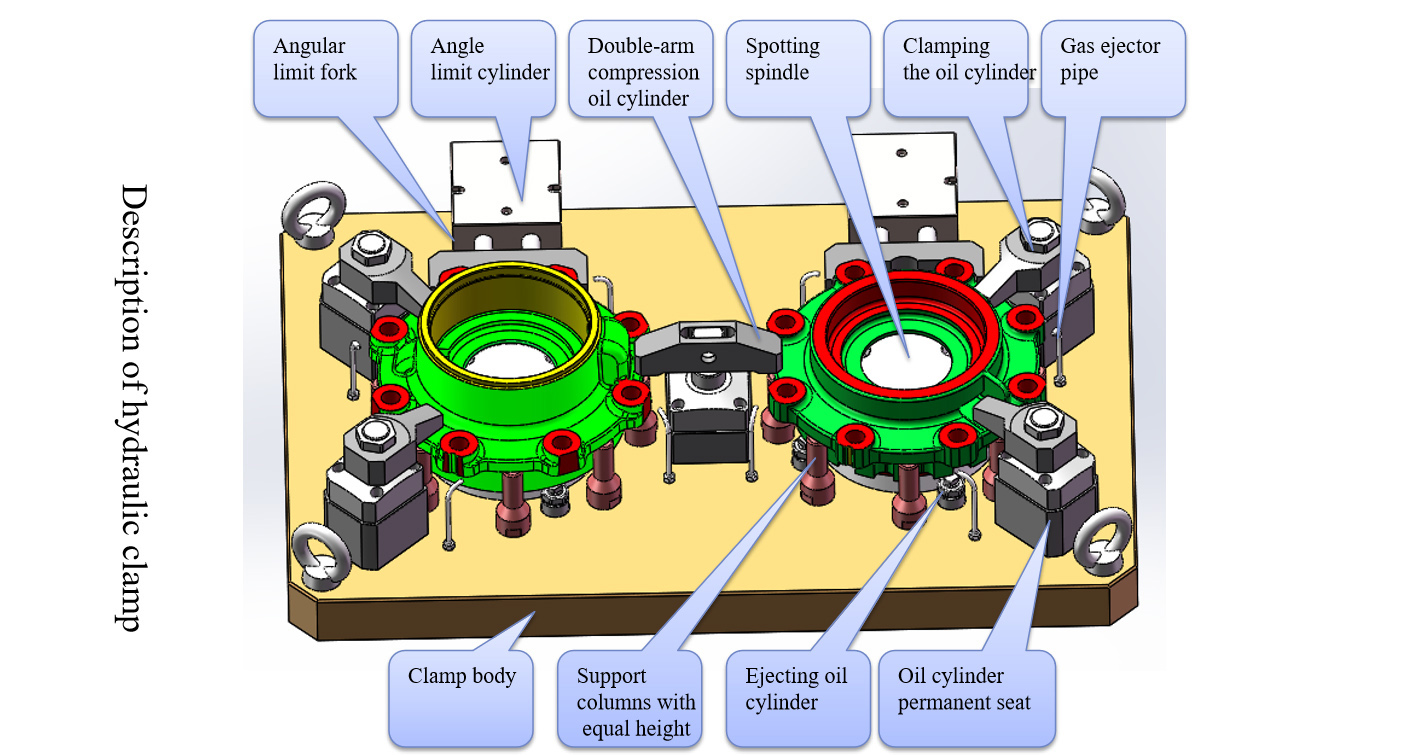

Ukwaziswa kwe-OP20 Hydraulic Fixture

Imiyalelo yokwenziwa komsebenzi:

1. Thatha i-φ165 yangaphakathi yomngxuma njengesiseko, thatha i-D datum njengesiseko senqwelomoya, kwaye uthathe i-arc yangaphandle yomphathi wemingxuma emibini yokunyuka njengomda we-angular;

2. Lawula isenzo sokukhulula kunye nokucinezela ipleyiti yokucofa ngomyalelo wesixhobo somatshini M ukugqiba ukuqhutyelwa kwe-chamfering ye-airplane ephezulu ye-hole hole boss, i-8-φ17 umngxuma wokunyuka kunye neziphelo zombini zomngxuma;

3. Uluhlu lunemisebenzi yokubeka indawo, i-clamping ngokuzenzekelayo, ukufumanisa ukuqina komoya, ukukhulula ngokuzenzekelayo, i-ejection ngokuzenzekelayo, ukugungxulwa kwe-chip ngokuzenzekelayo kunye nokucoca ngokuzenzekelayo ukubeka i-datum plane;

IiMfuno zeZixhobo zoMbane weMveliso

1. I-clamp yesixhobo somgca wemveliso inemisebenzi yokudibanisa ngokuzenzekelayo kunye nokukhulula, kwaye iqonda imisebenzi yokudibanisa ngokuzenzekelayo kunye nokukhulula phantsi kolawulo lweempawu zenkqubo ye-manipulator ukusebenzisana nokulayisha kunye nesenzo sokuvala;

2. Isikhundla sesibhakabhaka okanye imodyuli yocango oluzenzekelayo iya kugcinelwa ipleyiti yentsimbi yezixhobo zomgca wokuvelisa, ukulungelelanisa kunye nomqondiso wokulawula umbane kunye nokunxibelelana kwe-manipulator yenkampani yethu;

3. Isixhobo somgca wokuvelisa sinonxibelelwano kunye ne-manipulator ngokusebenzisa imodi yokudibanisa yomthwalo onzima (okanye iplagi ye-aviation);

4. Isixhobo somgca wokuvelisa sinendawo yangaphakathi (ukuphazamiseka) enkulu kunoluhlu olukhuselekileyo lwesenzo somhlathi we-manipulator;

5. Isixhobo somgca wemveliso siya kuqinisekisa ukuba akukho zitshiphu zentsimbi ezishiyekileyo kwindawo yokubeka ibamba. Ukuba kuyimfuneko, ukuvuthuza komoya kuya kwandiswa ukucoca (i-chuck iya kujikeleza xa icoca);

6. Isixhobo somgca wemveliso sinokuqhekeka okuhle kwe-chip. Ukuba kuyimfuneko, isixhobo esincedisayo sokuqhawula i-chip yenkampani yethu siya kongezwa;

7. Xa izixhobo zokuvelisa umgca zifuna ukuyeka ngokuchanekileyo kwi-spindle isixhobo somatshini, yongeza lo msebenzi kwaye unikeze iimpawu zombane ezihambelanayo;

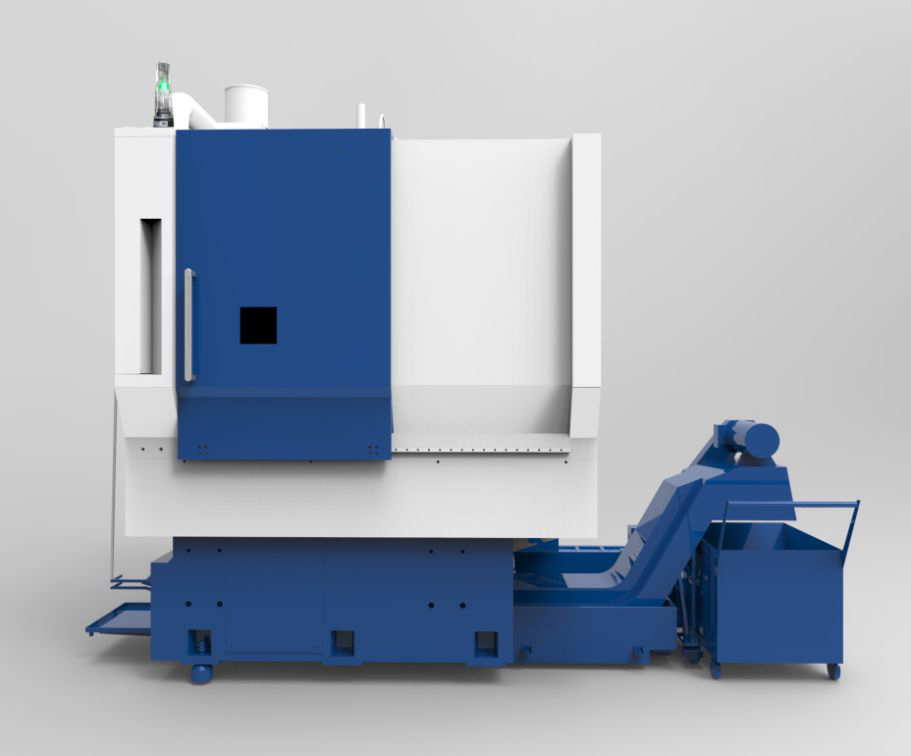

Ukwaziswa kwe-Vertical Lathe VTC-W9035

I-VTC-W9035 NC i-lathe ethe nkqo ifanelekile kumatshini ojikelezayo wamacandelo anje ngezixhobo zegiya, iiflange kunye namaqokobhe amise okwezodwa, alungele ngokukodwa, ukonga umsebenzi kunye nokujika ngokufanelekileyo kwamalungu afana neediski, iihabhu, iidiski zokuqhobosha, imizimba yempompo, imizimba yevalvu kunye namaqokobhe. Isixhobo somatshini sineenzuzo zokungaguquki kakuhle, ukuchaneka okuphezulu, isantya esikhulu sokususa isinyithi ngexesha leyunithi, ukugcinwa ngokuchanekileyo, ukuthembeka okuphezulu, ukugcinwa lula, njl njl kunye noluhlu olubanzi lwezicelo. Ukuveliswa komgca, ukusebenza kakuhle kunye neendleko eziphantsi.

| Uhlobo lwemodeli | I-VTC-W9035 |

| Ubukhulu bokuguqula ubukhulu bomzimba webhedi | Φ900 mm |

| Ubuninzi bokuguqula ubukhulu kwipleyiti yesilayidi | Φ590 mm |

| Ubukhulu bokuguqula ububanzi be-workpiece | Φ850 mm |

| Ubude obuninzi bokuguqula i-workpiece | 700 mm |

| Uluhlu lwesantya se-spindle | 20-900 r/min |

| Inkqubo | FANUC 0i - TF |

| Ubuninzi bokubetha kwe-X/Z i-axis | 600/800 mm |

| Isantya esihamba ngokukhawuleza se-X/Z i-axis | 20/20 m/min |

| Ubude, ububanzi kunye nokuphakama kwesixhobo somatshini | 3550*2200*3950 mm |

| Iiprojekthi | Iyunithi | Ipharamitha | |

| Uluhlu lokuqhubekekisa | X ukuhamba kwe-axis | mm | 1100 |

| X ukuhamba kwe-axis | mm | 610 | |

| X ukuhamba kwe-axis | mm | 610 | |

| Umgama ukusuka kwimpumlo yokusonta ukuya kwindawo yokusebenza | mm | 150-760 | |

| Indawo yokusebenza | Ubungakanani bebhentshi yokusebenzela | mm | 1200×600 |

| Ubuninzi bomthwalo webhentshi yokusebenza | kg | 1000 | |

| T-groove (ubukhulu×ubungakanani×isithuba) | mm | 18×5×100 | |

| Ukutya | Isantya sokutya ngokukhawuleza se-X/Y/Z axis | m/umz | 36/36/24 |

| I-spindle | Imo yokuqhuba | Uhlobo lwebhanti | |

| I-Spindle taper | BT40 | ||

| Esona santya siphezulu sokusebenza | r/min | 8000 | |

| Amandla (Ikaliwe/Eyona iphezulu) | KW | 11/18.5 | |

| ITorque (Ikalwe/Eyona iphezulu) | N·m | 52.5/118 | |

| Ukuchaneka | X/Y/Z ukuchaneka kokuma kwe-axis (isiqingatha esivaliweyo seluphu) | mm | 0.008 (ubude bubonke) |

| X/Y/Z ukuchaneka kophinda-phindo lwe-axis (isiqingatha esivaliweyo seluphu) | mm | 0.005 (ubude bubonke) | |

| Imagazini yesixhobo | Uhlobo | Icwecwe | |

| Umthamo wemagazini yesixhobo | 24 | ||

| Ubungakanani bobungakanani besixhobo(Isixhobo esipheleleyo sedayamitha/isixhobo esisecaleni esingenanto idiameter/ubude) | mm | Φ78/Φ150/ 300 | |

| Ubunzima besixhobo esiphezulu | kg | 8 | |

| Iintlobo ngeentlobo | Uxinzelelo lokubonelela ngomoya | MPa | 0.65 |

| Umthamo wamandla | KVA | 25 | |

| Ubungakanani besixhobo somatshini ngokubanzi (ubude×ububanzi×ubude) | mm | 2900×2800×3200 | |

| Ubunzima besixhobo somatshini | kg | 7000 | |